The lifespan of a spacecraft is a critical aspect of space exploration and the burgeoning industry of space tourism. Like any sophisticated machine, these marvels of human engineering require regular maintenance and repair to ensure they perform as intended over their operational life. Despite harsh conditions—extreme temperatures, vacuum, and radiation—spacecraft are expected to be resilient, but they aren’t impervious to wear and tear. Strategies for maintenance and repair are, therefore, crucial to maximize the lifespan and functionality of these vehicles. Agencies like NASA, along with private sector partners, continue to evolve practices and introduce robotic systems to carry out these vital tasks.

Further advancing the field, modern servicing and repair technologies have begun to allow for on-orbit assistance, including inspection, refueling, and even upgrading of spacecraft, which previously might have signaled the end of a mission. Autonomous systems and AI have further refined maintenance strategies, aiming to enhance the longevity of these space-bound assets. While the economic aspects of such operations are complex, the balance between cost and the need to ensure safety and risk management is equally intricate. This reflects a significant shift towards more sustainable and cost-effective spacecraft operations, influencing future directions in spacecraft servicing.

Maintenance concepts for spacecraft revolve around ensuring that these complex systems remain operational throughout their intended lifespan. The principles of safety, sustainability, and maintainability are at the core of these strategies. Given the nature of space, operations must be designed to be cost-effective while maximizing efficiency.

Space agencies and private companies are working on solutions to these challenges to ensure that as humanity reaches further into the cosmos, the vehicles they use to explore remain functional and effective.

The management of spacecraft life cycles involves critical contributions from NASA while facilitating international and commercial partnerships to achieve mission objectives.

NASA’s Reliability and Maintainability (R&M) program guarantees that systems within spaceflight projects meet their performance goals from launch through their designated life span. This includes partnering with entities like Northrop Grumman, which developed the Mission Extension Vehicle (MEV), showcasing a proactive step in life extension services for satellites. Collaborative undertakings at the International Space Station (ISS), involving multiple national space agencies, exemplify a collective effort toward sustainable space exploration.

These agencies often engage in the dissemination of knowledge, setting industry standards for spacecraft maintenance and repair. NASA leads such efforts, leveraging experiences in both manned and unmanned missions. Learned best practices are shared with international partners, which play a vital role in the continuing functionality of complex structures like the ISS, and with the private sector to enhance the longevity and safety of the hardware. This collaborative environment is essential for innovation in the space industry, guiding future endeavors in space exploration and tourism.

With the advent of advanced robotics and AI, the realm of spacecraft maintenance has undergone a significant transformation. These technologies aim to extend the operational life of spacecraft and reduce the need for manual intervention.

Recent advancements in space robotics have opened up new avenues for on-orbit servicing. Robotic systems can now perform complex tasks such as swapping out faulty hardware or patching up thermal blankets. For instance, the development of specialized robotic arms has made it possible to execute repairs that were once thought impossible without human astronauts. Companies are investing in robotic technologies to ensure satellites and spacecraft can be maintained efficiently and safely.

Artificial intelligence (AI) plays a crucial role in modern spacecraft maintenance. AI algorithms analyze vast amounts of data, diagnosing system anomalies and predicting when components might fail. This proactive approach to maintenance ensures that issues can be addressed before they evolve into serious problems. AI-driven tools are being integrated into spacecraft systems, leading to smarter and more reliable operations.

Autonomous solutions are redefining spacecraft maintenance by enabling systems that can self-diagnose and perform repairs without human intervention. This is particularly valuable in deep space missions, where communication delays make real-time human involvement impractical. Autonomy in spacecraft also means they can adapt to unexpected challenges, a critical capability for the success of long-duration space missions.

By integrating these technologies, the aerospace sector aims to significantly improve the sustainability of spacecraft operations, ensuring a robust and resilient presence in the cosmos.

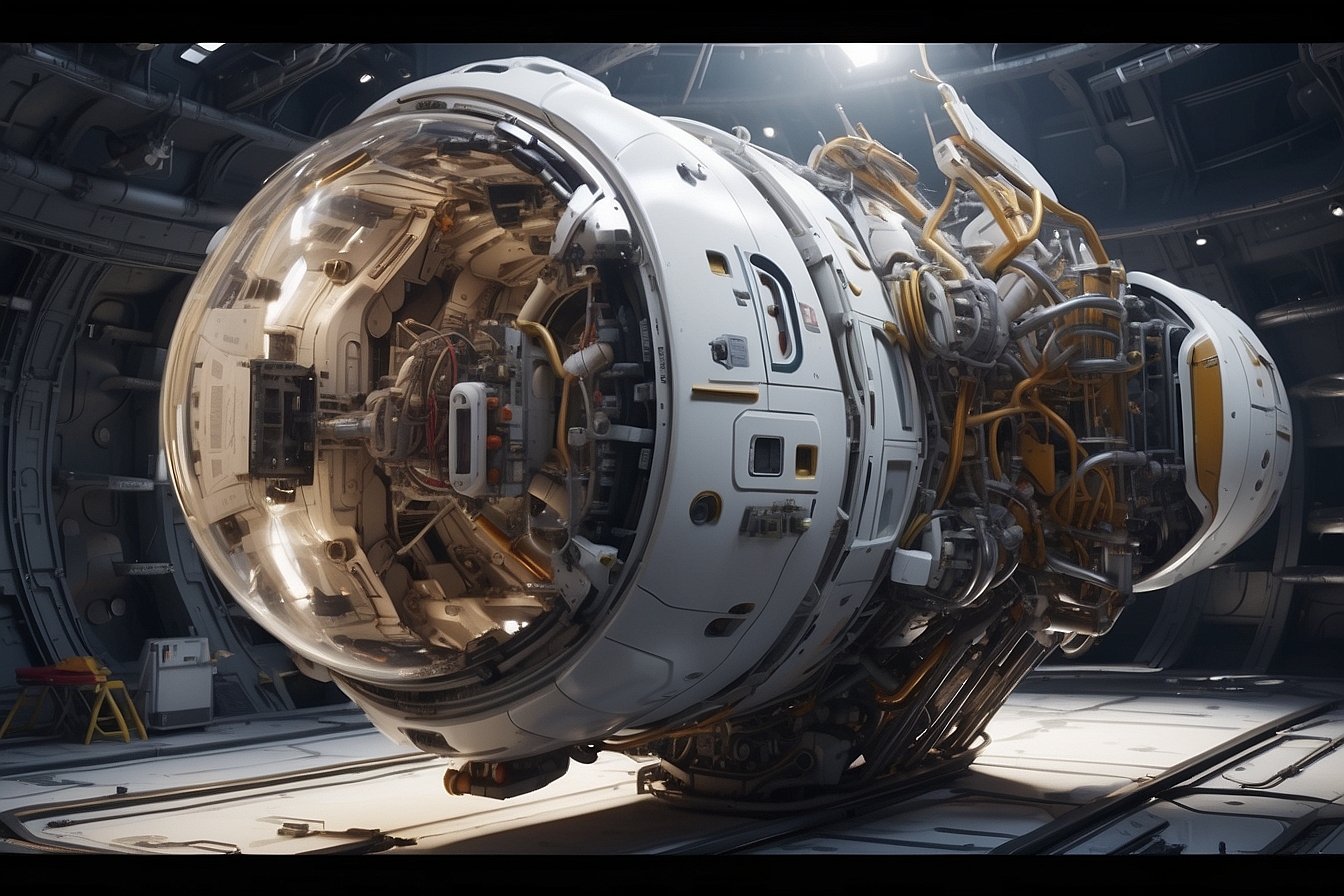

The maintenance and repair of spacecraft are essential for mission success, and advancements in technology have led to innovative strategies to extend their operational lifespan. These techniques not only increase the duration of missions but also optimize the utilization of resources in space.

The Mission Extension Vehicle (MEV) represents one of the most significant breakthroughs for prolonging spacecraft lifespans. An MEV is designed to dock with a geosynchronous satellite, providing not only stability and control but also additional propulsion and power, thereby extending the satellite’s lifespan. Each MEV can facilitate numerous docking and undocking maneuvers, which supports multiple missions throughout its own 15-year design life.

Refueling and Resupply Operations are critical to maintaining spacecraft over extended periods. This involves complex maneuvers to transfer fuel and other essential supplies, ensuring that vital systems, including propulsion, remain operational. Techniques developed for in-orbit services enable such direct support, which could significantly extend a satellite’s functional lifespan and defer the substantial costs of launching replacements.

In orbit, satellite repair and maintenance activities are becoming more practical, similar to servicing vehicles on Earth. Implementing in-space repairs and technological upgrades enhances performance and can address unforeseen issues, thereby reducing the risks of mission failure. With the ability to replace or fix components, satellites could surpass their intended operational life, contributing to a more effective and sustainable presence in space.

Navigating the financial complexities of maintaining and operating spacecraft is critical for ensuring their longevity and reliability. This section explores the economic side of spacecraft management, focusing on the cost-effectiveness of servicing missions and their impact on the telecommunications industry.

In-space servicing missions are a crucial strategy for maximizing the investment in spacecraft. These missions can involve inspection, repair, refueling, and upgrading of satellites already in orbit. By extending the operational life of spacecraft, servicing missions reduce the need for immediate replacements, thereby saving costs on designing, testing, and launching new satellites. A specific study predicts that routine spacecraft refueling and servicing could avoid decommissioning and significantly prolong satellite lifetimes within the next decade. The economic implications of such advancements include decreased insurance premiums and deferred manufacturing and launch costs.

Advantages of Servicing Missions:

The telecommunications industry greatly benefits from the extended service life of spacecraft, as satellites play a pivotal role in facilitating global communications. Performing on-orbit servicing can directly influence and bolster the reliability and performance of these satellites, which in turn can significantly impact the economic aspect of the telecommunications sector. A more dependable fleet of satellites means enhanced service provision to customers, reduced service interruptions, and the potential to offer new services. The economic return on these missions can be considerable, as the cost of servicing is often lower than the potential revenue generated by extended satellite operations.

Key Influences on Telecommunications:

By carefully considering the cost-effectiveness of servicing missions and their economic impact on industries such as telecommunications, spacecraft operators can optimize their investments and continue to push the boundaries of space utilization.

In the vast expanse of space, strategic planning for safety and risk management is paramount. Sustainable space travel and satellite operations rely on robust measures to manage the various dangers spacecraft can encounter, from harsh space weather to the potential for in-orbit collisions.

Space weather, including solar flares and cosmic radiation, can adversely affect spacecraft electronics and communications. During periods of solar maximum, the heightened activity can lead to more frequent and severe solar events. Engineers design spacecraft with shielding that minimizes exposure to solar radiation and includes redundancies to safeguard critical systems.

Space debris poses a significant collision risk to active spacecraft. To mitigate this danger, satellite operators employ tracking systems to monitor debris and provide early warnings. A satellite’s ability to perform maneuvers to avoid collisions is a critical part of operational protocols. Additionally, operators adhere to guidelines for satellite separation to prevent proximity issues in densely populated orbits.

At the conclusion of a spacecraft’s mission, responsible decommissioning is a key aspect of risk management. This typically involves moving the spacecraft to a graveyard orbit where it is less likely to pose a collision risk, or deorbiting it to ensure a safe, controlled re-entry. These end-of-life strategies are vital to maintaining the long-term sustainability of low Earth orbit by minimizing the accumulation of debris.

In the harsh environment of space, repairing and maintaining spacecraft requires specialized tools and equipment. Astronauts and technicians rely on these meticulously designed items to perform tasks outside the bounds of Earth’s atmosphere.

In the vacuum of space, standard Earth tools are ineffective. The extreme temperatures and lack of air pressure necessitate the design of tools that can withstand these conditions. For instance, the tools used during the Hubble Space Telescope servicing missions were uniquely crafted for the task. They incorporated features such as tether points to prevent accidental drifting away and were operable even when technicians wore bulky space gloves.

To assist the astronauts who serve as technicians in space, tools must also enhance their capabilities. Space tools are designed to be lightweight and easy to maneuver, often incorporating versatility and multifunctionality to reduce the number of tools needed for a repair. Portable power tools used on the International Space Station (ISS) allow for efficient servicing tasks, enabling astronauts to complete repairs that would otherwise be impossible with manual labor alone.

As the field of space exploration evolves, new technologies and strategies for spacecraft maintenance and repair are steadily emerging. Advancements in propulsion systems and a host of emerging technologies promise to enhance the longevity and reliability of spacecraft.

The advent of novel propulsion systems has the potential to revolutionize spacecraft servicing. For instance, the application of electric propulsion could extend the missions of satellites by providing more efficient thrust for orbital maneuvers and station-keeping. This high-efficiency propulsion could reduce the fuel load, allowing for additional payloads or longer mission durations. The Solar Maximum Mission utilized the Space Shuttle for on-orbit servicing, demonstrating the viability of spacecraft repair and the potential benefits of having a propulsion system that allows for such close-range operations.

The conjunction of autonomous guidance systems, attitude control, and advanced sensors is reshaping in-orbit servicing. The Orbital Express mission highlighted autonomous on-orbit refueling and component replacement, which can now be taken further with technologies like NEXSAT. By integrating these technologies, spacecraft can perform intricate repair tasks with minimal human oversight. Robotic arms and remote sensing instruments pave the way for non-intrusive inspections and repairs, potentially increasing mission lifespans and reducing risks associated with extravehicular activities.

In this section, we’re addressing some of the most common inquiries related to the longevity of spacecraft. These questions touch on the lifespan, maintenance, challenges, and technological progress in spacecraft operations.

Several elements influence the operational lifespan of satellites and spacecraft, including the durability of their components, exposure to the harsh environment of space, and the ability to perform successful maintenance and repairs. Thermal cycling, radiation, and micro-meteoroid impacts are also contributing factors.

In-orbit maintenance typically includes system check-ups, software updates, and hardware replacements or repairs. Some missions may also involve refueling and intricate repair tasks, which can be carried out by astronauts during spacewalks or by utilizing robotics.

The frequency of maintenance for satellites varies, depending on their design and mission requirements. Some may operate for years without the need for hands-on maintenance, while others might have scheduled periodic checks and repairs to ensure continued functionality.

Yes, performing repairs on a spacecraft after it has been launched is possible. On-orbit servicing missions may include tasks such as hardware replacement, inspection, refueling, and upgrading. These operations are complex and require careful planning and execution.

Engineers grapple with challenges like ensuring long-term reliability of components, minimizing the impact of space radiation, and providing adequate power supply throughout the mission. Designing spacecraft for autonomy and ease of maintenance is crucial for extended missions.

Advancements in technology can lead to significant improvements in the efficiency and effectiveness of satellite maintenance and repair strategies. Innovations in robotics, on-orbit servicing methods, and the use of AI for predictive maintenance shape how these critical services evolve.