Thermal protection systems (TPS) are critical components in ensuring the safety and integrity of space vehicles. They protect the structure and payload of the spacecraft from the extreme temperatures encountered during atmospheric entry and re-entry. The temperatures can exceed 1,650 °C, which would otherwise destroy the vehicle. Therefore, TPS technology involves a combination of materials science, aerodynamics, thermodynamics, and engineering design to create a barrier that can withstand severe heat and protect the vehicle’s contents.

The design process of a thermal protection system is complex and must account for various factors such as the type of mission, the vehicle’s velocity, atmospheric density, and heat flux. Materials used in TPS are chosen for their thermal properties, including high melting points and thermal shock resistance. The TPS must also integrate seamlessly with the rest of the spacecraft to ensure its functionality and safety, as well as optimise the vehicle’s performance.

In this section, we delve into the core aspects of thermal protection systems (TPS), discussing their historic evolution and the principles that govern their function. It’s critical to recognise that both the materials used and the design principles behind TPS are central to the safety and efficiency of spacecraft during the extreme conditions of re-entry.

The development of TPS has been a response to the stringent demands of space travel, particularly during the high-heat phases of spacecraft re-entry. Early iterations of spacecraft utilised simple ablative materials that would erode away as they absorbed the intense heat flux. These were largely non-reusable systems, tailored to withstand the aerodynamic stresses and temperature extremes encountered just once. Over time, reusable TPS arose, changing the landscape of space flight safety and economy.

TPS are fundamentally designed to shield spacecraft from the harsh thermal environment encountered during high-speed travel through an atmosphere. Two critical functions define these systems:

The design of TPS is heavily influenced by the expected heat flux levels, which dictate the level of insulation needed. Reusable TPS, although more complex in design, result in significant savings over multiple flights as seen in the development of the Space Shuttle. The efficiency of TPS is a balance between the weight of the materials and their insulative properties, striving to maximise payload capacity without compromising the vehicle’s temperature management or safety.

In this section, we focus on the innovative materials and technologies that form the backbone of thermal protection systems (TPS) in aerospace engineering. These breakthroughs are crucial for safeguarding space vehicles against extreme temperatures.

The selection of materials for thermal protection is pivotal to the performance of space vehicles under aerothermal heating. Lightweight and mass efficient TPS materials, such as Ceramic Matrix Composites (CMCs), offer enhanced durability and thermal stability. These materials can withstand the intense heat generated during atmospheric re-entry. CMCs also provide a balance between weight and resilience, traits essential for space exploration.

Our advancements in TPS technologies focus on improving the safety and efficiency of space travel. For instance, we deploy advanced modelling and simulation tools to predict and analyse the behaviour of new thermal protection materials. By making TPS components more lightweight and effective at insulating against heat, we help reduce the overall mass of space vehicles.

Advanced systems typically consist of:

Embracing these materials and technologies, we ensure the safety and effectiveness of space travel, contributing to exciting prospects for ventures like those envisioned by SpaceVoyageVentures.com.

In this section, we discuss the essential aspects of designing thermal protection systems (TPS) and the advanced computational methods utilised to model these critical systems. We delve into the factors that guide the design process and explore how modelling and simulation tools contribute to the creation of effective TPS solutions.

When engineering a TPS, we must consider a variety of factors to ensure the system’s efficiency and reliability. The choice of materials is paramount, and we often use simple materials such as aluminium foil, or more sophisticated ablative materials to resist extreme temperatures. The design must account for the anticipated heat fluxes and pressure loads, structural integrity, and also the mass efficiency of the TPS, as excess weight is a critical concern in aerospace applications.

Our approach to modelling and simulation tools is rooted in the development of reliable and accurate computational methods. We apply various simulation tools to predict the behaviour of TPS materials under different conditions. Using techniques like finite element analysis (FEA), we can simulate the thermal stresses and strains that a TPS will encounter during re-entry. Additionally, computational fluid dynamics (CFD) allows us to assess the aerothermal environment that the system will face. An effective modelling process significantly enhances the design by providing insights that inform material selection and structural design, thus ensuring our spacecraft can withstand harsh re-entry conditions.

To ensure the efficacy and reliability of thermal protection systems (TPS), laboratory testing and simulation techniques play pivotal roles. Our ability to predict the performance of TPS materials in the extreme conditions of space travel hinges on rigorous testing and advanced simulation methodologies.

In our pursuit for space vehicle safety, we conduct comprehensive thermal testing of TPS materials. These tests are critical to ascertain the materials’ ability to withstand intense heating, which varies depending on vehicle shape, speed, trajectory, and atmospheric conditions. The NASA Ames Research Centre has protocols in place that simulate these conditions, aiming to replicate the severe heating and pressure encountered during vehicle re-entry.

Alongside physical tests, robust simulation tools are employed to evaluate TPS performance. Our use of multi-input and multi-output support vector machines (MIMO-SVMs) facilitates a comprehensive reliability sensitivity analysis. These tools, such as the one reviewed in Reliability sensitivity analysis of thermal protection systems, help us understand the behaviour of temperature-dependent materials used in TPS under various conditions. Furthermore, advancements in computational tools, including software like Mentat, enhance our ability to model and predict how TPS structures will fare in the harsh environments of space.

In this section, we’ll explore the critical roles thermal protection systems (TPS) play in current space endeavours, from safeguarding spacecraft during extreme temperature exposures to ensuring the safe return of samples from space.

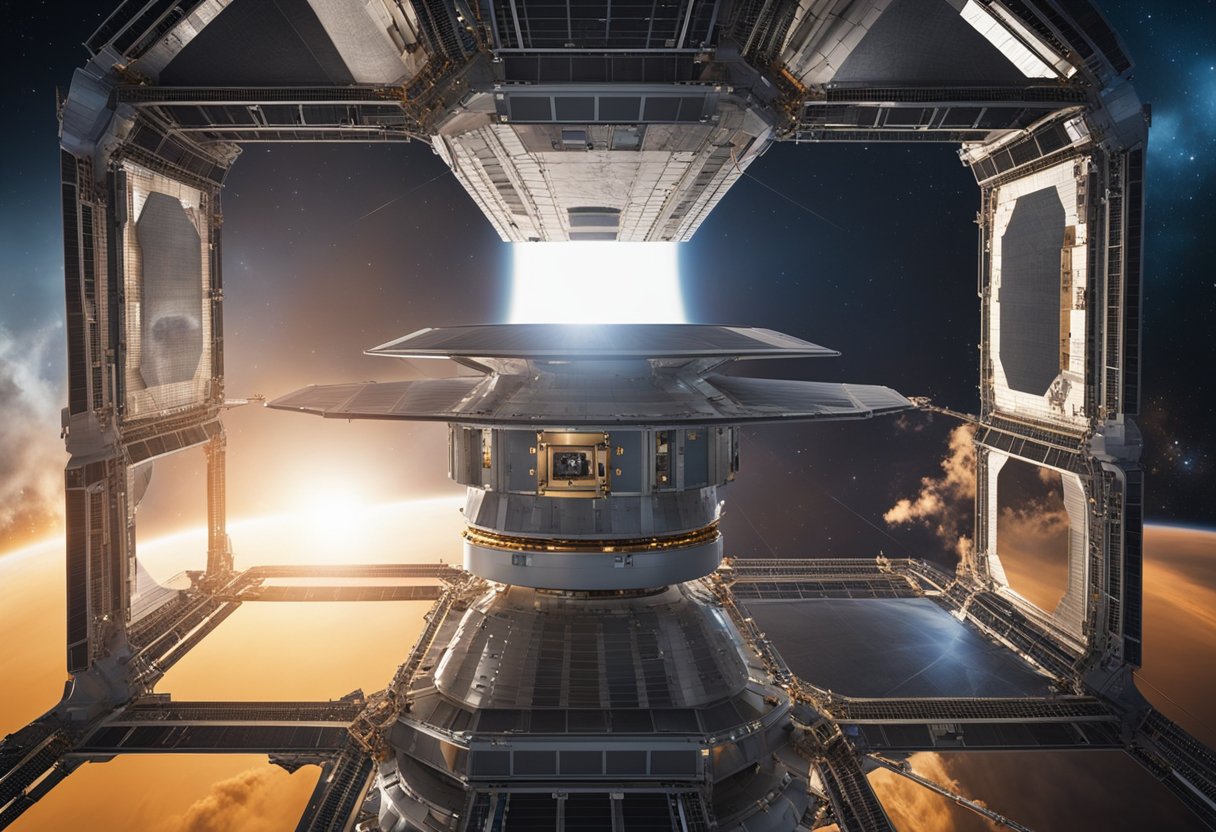

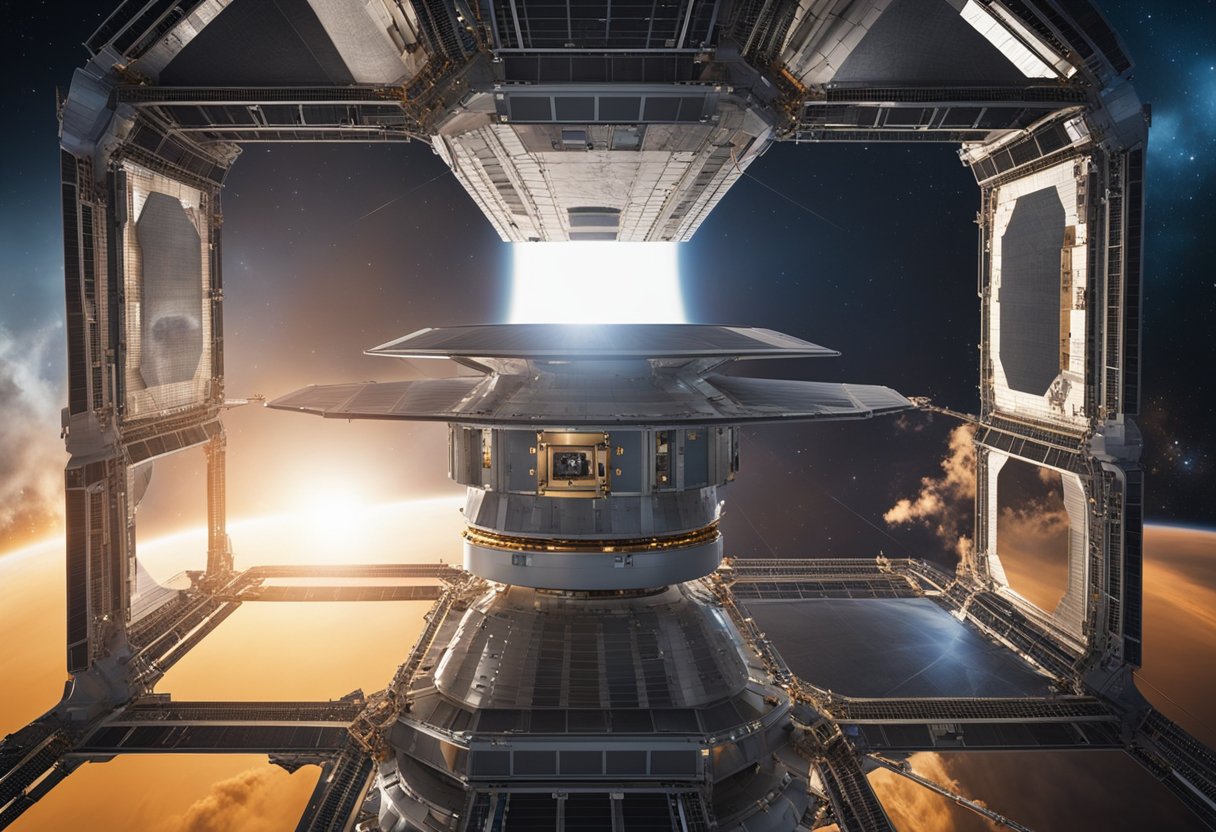

Our continuous quest to explore space relies heavily on spacecraft equipped with robust TPS to withstand the intense heat generated during launch and space travel. These systems are vital for maintaining structural integrity and functionality of spacecraft. The development of TPS technology has been crucial in advancing our capabilities for missions beyond Earth’s orbit. Passive, semi-passive, and active thermal protection systems have been under continuous improvement to meet the challenges of increasingly ambitious space exploration goals. For reusable launch vehicles, which have become a cornerstone in space programmes, effectively managing thermal loads is indispensable not only for safety but also for economic viability.

As we endeavour to bring materials back from space, reentry vehicles with sophisticated TPS are essential in safeguarding the precious payload within. These systems ensure that capsules can endure the scorching heat of reentry and keep contained samples intact. NASA’s Ames Research Center has been instrumental in developing high-temperature reusable surface insulation tiles for these purposes. Moreover, sample return missions such as those from the Moon, Mars, and asteroids are rendered possible through advances in TPS, thereby enhancing our scientific understanding of the universe and answering long-held questions about our place in it.

In confronting the rigours of space travel, we navigate through extreme aerodynamic and thermal challenges that push the limits of modern engineering. Our foray into hypersonic velocities introduces unique hurdles in the design and functionality of thermal protection systems (TPS).

At hypersonic speeds—classified as speeds greater than Mach 5—aircraft and space vehicles encounter phenomena not present in lower-speed flight. The thinning atmosphere at high altitudes in combination with hypersonic velocities can lead to rarefied gas dynamics. This environment requires us to consider multiple factors such as non-continuum aerodynamics and the associated changes in air properties. Hypersonic flight significantly increases the difficulty of predicting and managing the aerodynamic forces acting upon a spacecraft. These high-speed conditions also contribute to the formation of shock waves that envelop the vehicle, altering pressure and temperature distributions across its surface.

During atmospheric re-entry or high-speed flight, significant aerodynamic heating occurs. Materials and structures on hypersonic vehicles must withstand severe heating due to atmospheric friction. At hypersonic speeds, the kinetic energy of the airflow converts into intense heat, which can cause surface temperatures to soar to thousands of degrees Celsius. Heat flux into the TPS can reach critical levels, necessitating the development of advanced materials and structures to prevent the vehicle’s internal temperatures from rising to unsafe levels. Hypersonic speeds also amplify the effects of aerodynamic heating, making the design of a robust TPS even more crucial. Our exploration of space endeavours requires us to create innovative TPS solutions that can endure these extraordinary conditions.

In the realm of space travel, safeguarding the integrity of thermal protection systems (TPS) is critical for ensuring the safety of both vehicle and crew during the high-stress phases of launch and re-entry. Our focus here is to elucidate the stringent safety criteria and the comprehensive risk management strategies that govern these systems.

Safety Criteria: It is imperative that the TPS is designed to withstand the intense heat and friction encountered during a spacecraft’s re-entry into Earth’s atmosphere. The criteria include:

The evaluation and prediction of TPS performance, as noted in a NASA Ames Research Center document, are essential in designing a TPS that meets these safety criteria. Also, ensuring the reliability of the materials and the reproducibility of their manufacturing processes is non-negotiable to comply with safety standards.

Risk Mitigation: Risk management involves a multi-tiered approach:

The reliability sensitivity analysis of the TPS is key to risk management, supporting the selection of materials and configurations that can reliably protect the spacecraft. It is a method for assessing how changes in design variables affect system reliability, thus ensuring robust safety margins.

Our consistent commitment to safety and reliability in the design and testing of thermal protection systems establishes us as leaders in the space industry’s future developments, including burgeoning sectors like space tourism. At SpaceVoyageVentures.com, we document the advancements that pave the way for safe space travels. Our unwavering confidence in the systems we advocate stems from a knowledge base steeped in evidence and rigorous assessment.

As we explore the most cutting-edge advancements in thermal protection systems (TPS), it’s essential to acknowledge two strategic directions that are shaping the future of spacecraft technology. Active thermal protection systems (TPS) and adaptive, responsive TPS solutions are at the forefront of enabling longer, more demanding missions into deep space.

Active TPS employ mechanisms that actively control the thermal state of a spacecraft. This can include systems that circulate fluids, like coolants, to absorb and redistribute heat, or those employing electrical means to resist extreme temperatures. NASA technology roadmap has identified active TPS as a key area for development, as these systems facilitate precise temperature management critical for preserving spacecraft integrity during high-heat events such as atmospheric re-entry or close solar passes.

Adaptive and responsive TPS are designed to react and adjust to the varying thermal environments encountered in space. These systems might incorporate materials that change their properties in response to temperature fluctuations, or structural features that can alter their configuration to dissipate heat more effectively. Providing a dynamic approach to heat management, these TPS strategies are vital for missions with diverse thermal requirements, pushing the boundaries of what’s achievable with traditional TPS solutions.

In this section, we’re delving into the crucial components and processes behind monitoring the integrity of Thermal Protection Systems (TPS). We’ll explore the specifics of sensors and the technology used to collect and analyse data.

TPS sensors are integral to the safety and functionality of space vehicles, enabling the measurement of temperature and heat flux. These sensors need to withstand extreme conditions, allowing for real-time monitoring during a spacecraft’s launch and re-entry. For instance, sensors capable of simultaneous measurement of temperature and heat flux have been developed to support the validation of TPS. They are vital for verifying ground-based sizing tools that integrate computational fluid dynamics and material response modelling with testing data.

Measurement systems for TPS involve sophisticated data acquisition and analysis components. These systems collect critical sensor data, which must then be accurately and swiftly analysed to ensure the TPS is functioning correctly. For example, dual measurement of optical surface inspection and subsurface sensor technology aids in both validating the structural integrity of the TPS and in diagnosing potential issues. Data analysis is performed using advanced software capable of pattern recognition, significantly enhancing our knowledge about the performance of TPS materials and designs under the harsh environmental conditions experienced during spaceflight.

In ensuring the safety and efficiency of space-bound vehicles, a paramount aspect to consider is how thermal protection systems (TPS) blend with the overall design for optimal payload security and integration.

Payloads are the crucial components or instruments that spacecraft are designed to transport and deploy. Ensuring their protection during the severe conditions of atmospheric re-entry is imperative. Utilising advanced TPS technologies, such as those found in ScienceDirect’s review, allows payloads to withstand high thermal loads. Moreover, the state of the art in TPS is geared towards lightweight solutions that do not compromise the safety or structural integrity of the payload.

Innovative approaches, such as deployable systems described in NASA’s research, have facilitated the design of TPS for aerospace vehicles that expand and protect payloads upon atmospheric entry. These scalable solutions can cater to a range of vehicle designs and mission requirements.

The integration of TPS is not merely about protection; it’s about incorporating the system seamlessly with the vehicle’s aerodynamic and structural design. As we move towards multi-functional spacecraft, such as those with Integrated Thermal Protection Systems (ITPS), these TPS not only shield against high temperatures but also contribute structurally to the spacecraft. The design and analysis of these integrated systems show a merger of functionality that boosts overall mission performance, allowing for more design space within the vehicle.

Furthermore, we see innovative control design being integrated into TPS for improved efficiency. The technologies discussed in NASA’s Pterodactyl project highlight how TPS is evolving to become a vital part of the vehicle’s control system, affecting not just the protection of payloads but also the manoeuvrability and stability of the vehicle throughout re-entry.

In this section, we address some of the most common inquiries regarding thermal protection systems used in space exploration. Each subsection below offers insight into the specifics of how these systems are designed, their operational mechanisms, and the materials that are critical to their function.

Thermal protection systems protect spacecraft from the extreme temperatures experienced during atmospheric entry and re-entry. These systems typically use insulation or ablative materials to absorb and dissipate heat, ensuring structural integrity and the safety of onboard instruments.

Active thermal protection systems utilise mechanisms such as cooling loops or heat pumps to manage temperature, whereas passive thermal protection systems rely on materials that absorb, reflect, or dissipate heat without moving parts or supplementary systems.

The primary materials for thermal protection systems include insulative ceramics, ablative materials, like the Phenolic Impregnated Carbon Ablator (PICA), and refractory metals. These materials are chosen for their thermal stability and resistance to aerodynamic heating.

Several companies specialise in the production of thermal protection systems, although a definitive list is proprietary. Notable entities such as NASA’s Ames Research Center are at the forefront of developing advanced thermal protection systems and materials.

Thermal limit protection refers to the safeguards like thermal protectors within electronic systems that prevent overheating by interrupting the power supply when a pre-set temperature is exceeded. This ensures the longevity and safe operation of electrical devices.

Designing thermal protection for hypersonic vehicles revolves around managing extreme aerothermal heating. Materials must withstand high temperatures and thermal cycling. Designers also consider factors like weight, durability, and reliability at Mach 5 speeds and above.