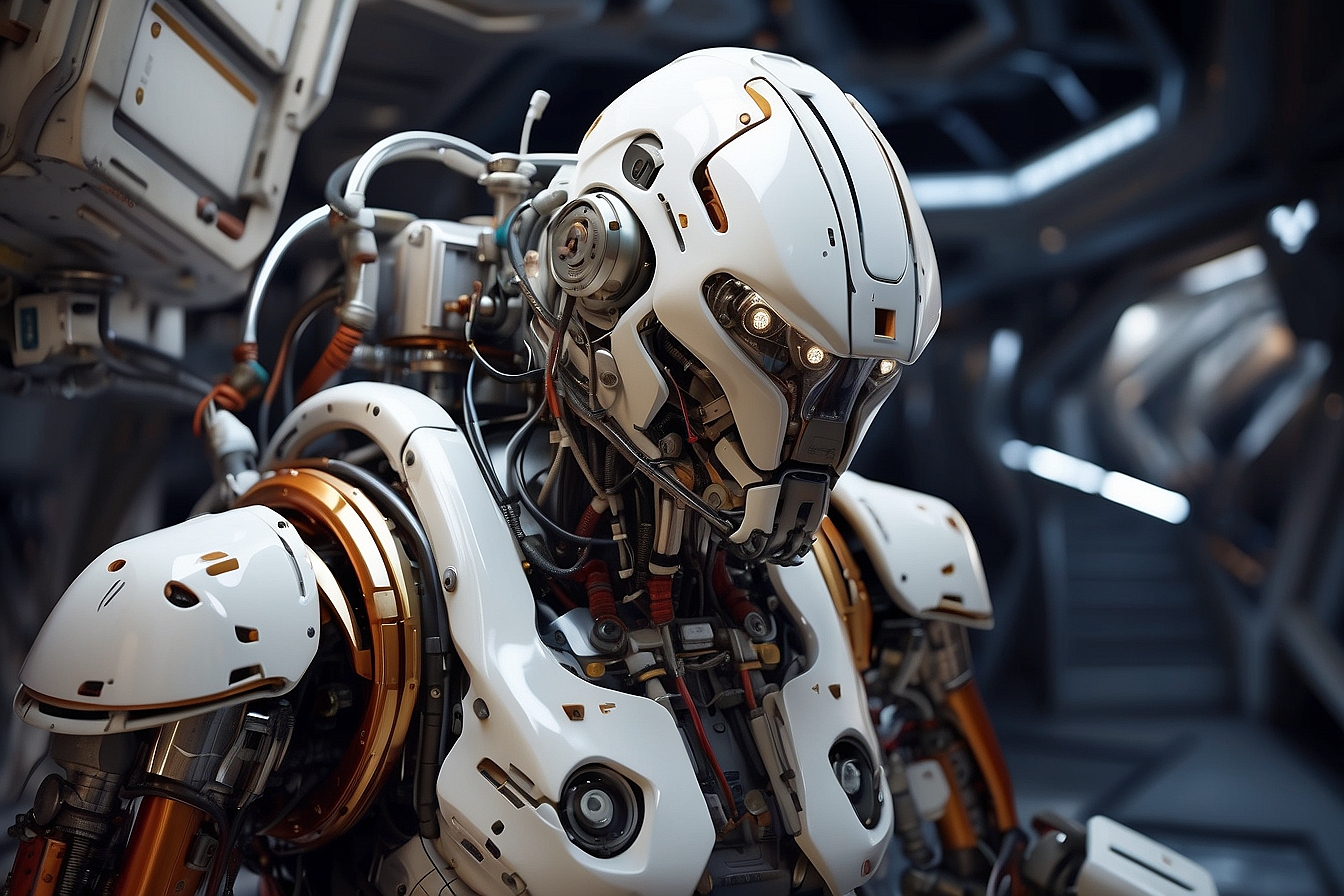

Robotics in Spacecraft – Robots have revolutionized many industries on Earth, and their impact extends beyond our planet to the ever-expanding realm of space exploration. In the high-stakes environment of space, robotics plays a crucial role in the assembly and maintenance of spacecraft. The physical limitations and significant risks associated with human spacewalks have made robotic assistance not just valuable but often essential. These robotic systems are designed to perform intricate tasks, ranging from the construction of vast space stations to the repair and refuelling of satellites.

Robots in space must operate under extreme conditions, facing challenges like vacuum, microgravity, and radiation that would be insurmountable for humans alone. As technology progresses, these robotic assistants are equipped with more autonomy and advanced capabilities, enabling them to undertake complex missions with reduced direct human oversight. This shift not only improves safety but also increases the efficiency and longevity of space infrastructure, pushing the boundaries of what is achievable in space exploration and satellite servicing.

The use of robotics in space exploration has undergone remarkable transformations, from simple mechanical appendages to highly autonomous agents capable of complex tasks.

The Canadarm2, a sophisticated robotic arm installed on the International Space Station (ISS), marks a significant leap from its predecessor, which deployed and retrieved payloads on the Space Shuttle. This advanced system is a crucial tool for the ISS, supporting spacecraft maintenance and maneuvering large objects in the harsh environment of space.

In parallel, the development of Robonaut 2 represents another evolutionary stride, signifying the potential of humanoid robots in assisting astronauts. Unlike its purely mechanical counterparts, Robonaut 2 is designed to interact with the same tools and interfaces as human crew members, allowing for a shared workload and more efficient task management.

The German Aerospace Center (DLR) plays a pivotal role in the advancement of space robots. Their contributions have broadened the scope of space automation and robotics, focusing on robots that are adept at precise and dexterous tasks. The DLR’s innovations not only support ongoing space missions but also lay the groundwork for future exploration scenarios where robots may play even more integral roles.

The advent of sophisticated robotics has revolutionized how spacecraft are assembled, enabling increasingly complex missions. Cutting-edge technologies facilitate the intricate construction and maintenance of spacecraft components in the harsh environment of space.

Automation plays a pivotal role in the assembly of space systems. It not only enhances precision and reliability in the construction of spacecraft but also significantly reduces the risk to human life. Automated space robotics technologies can perform tasks such as connecting solar panel modules or assembling large-scale structures. Systems like the Dragonfly will further advance these capabilities by demonstrating autonomous in-orbit assembly of significant space infrastructure components.

The development of space manipulators is crucial to the functionality of space robotics technologies. These sophisticated robotic arms must offer multi-degrees of freedom and advanced control systems to perform intricate tasks like on-orbit repairs and maintenance. An excellent example of innovation in this area includes advancements in vibration suppression and compliant assembly techniques for space systems, as discussed in a recent survey of space robotic technologies. These developments are not only critical for current missions but also for the ambitious endeavors of future space exploration, which demand robust and intelligent robotic systems capable of large-scale in-space assembly.

In the field of space exploration, on-orbit servicing (OOS) is a vital area encompassing techniques and technologies that enable servicing spacecraft to dock, berth, refuel, and repair satellites in space. These capabilities represent a transformative approach to satellite maintenance, potentially extending missions and reducing space debris.

Docking involves the connection of a servicing spacecraft with another spacecraft in orbit, typically to perform maintenance or transfer materials. This procedure requires precise navigation and control to align two space vehicles and join them together. Berthing, on the other hand, is a process where a servicing spacecraft is maneuvered to proximity and then is connected to the host vehicle using robotic arms. Both methods are critical for OOS, as they serve as the initial steps for any servicing mission and pave the way for various maintenance activities.

Once a service vehicle has docked or berthed, refueling operations can commence. This is a delicate task that involves transferring propellant from the servicing spacecraft to the client satellite to extend its functional lifespan. Repairing, another crucial function of OOS, may involve tasks like replacing faulty components, mending solar panels, or fixing thermal blankets. By allowing in-situ repairs, the longevity of satellites is greatly enhanced, thereby reducing the cost and frequency of launching new satellites.

Effective path planning and control are critical in the realm of space robotics, where precision and adaptability to the unique challenges of microgravity are paramount.

In microgravity environments, trajectory design for space robots becomes a sophisticated task due to the absence of gravitational forces found on Earth. Complex algorithms are required to handle six degrees of freedom for movement, which includes three rotational and three translational motions. One such approach in trajectory design involves creating a virtual assembly environment based on CAD models of spacecraft components to validate the paths in a simulated setting before actual deployment.

Control systems for space robotics can be categorized into two types: automated and manual. Automated control systems leverage machine learning strategies to optimize path planning, ensuring efficiency and reducing the potential for human error. Conversely, manual control systems rely on astronauts or ground operators to control robotic arms, which requires careful consideration of the dynamic coupling between the robot’s arms and its base in space. Both systems play a pivotal role in the successful assembly, maintenance, and repair of spacecraft.

Effective maintenance of spacecraft systems is essential to ensure the longevity and reliability of missions. It encompasses routine inspections, timely repairs, and strategic preventive measures.

Routine inspection and upkeep are fundamental to spacecraft maintenance. They involve the systematic checking of all spacecraft components to detect issues before they escalate. Robotic systems are increasingly employed to perform these tasks, providing detailed inspections without risking human lives. For example, they can inspect a target spacecraft for damage to its exterior or signs of wear and tear on its solar panels.

Maintenance strategies for spacecraft systems fall into two primary categories: reactive and preventive. Reactive maintenance addresses problems as they arise, while preventive maintenance is conducted to prevent issues before they occur. The use of robotics in preventive maintenance is particularly notable; these technologies can help refuel, repair, or upgrade spacecraft, such as by replacing outdated instrumentation or damaged hardware on a target spacecraft. This shift toward proactive maintenance is poised to significantly enhance mission success rates and safety.

Within the realm of space exploration, robotics serves an indispensable role in both the assembly and maintenance of spacecraft. However, developing and deploying these robotic systems in the harsh environment of space involves overcoming substantial challenges.

Space robots must navigate an environment cluttered with debris, ranging from spent rocket stages to fragments from satellite collisions. Debris removal is a critical and complex task, as the robots need to identify, capture, and safely discard or repurpose the debris. This involves intricate maneuvering to avoid contributing to the already perilous conditions of low Earth orbit.

For effective on-orbit assembly and repair, a higher level of dexterity and autonomy is essential. Robots in space must possess the capability to handle delicate components with precision and adapt to unforeseen issues. Intelligence enhancements, such as the ability to make decisions based on sensory inputs, are vital to carry out intricate tasks without direct human control.

The integration of advanced algorithms and machine learning techniques contributes significantly to improving the dexterity and intelligence of space robots, making them more reliable and efficient in performing complex operations autonomously.

The acceleration of technological advancements is setting the stage for revolutionary changes in space robotics. These developments hold the promise of enhanced efficiency and broader capabilities in spacecraft assembly and maintenance.

Next-generation robotic solutions are poised to redefine the landscape of space operations. Space robots equipped with cutting-edge software will carry out complex assembly tasks with unprecedented precision. The advent of modular robotic systems enhances in-space servicing and assembly, as highlighted by the MOdular Satellite Assembly and Reconfiguration (MOSAR) project. These systems articulate a step towards a sustainable space environment, offering reusable spacecraft modules that serve as a foundation for an interoperable ecosystem in space.

In preparation for interplanetary missions, collaborative space robotics stand out as a critical component. The integration of space robots to assist and eventually replace humans in dangerous or repetitive tasks during long-duration missions to Mars or the Moon speaks volumes about their future role. This collaboration relies on a fine balance between semi-autonomous systems and fully autonomous operations to ensure the safety and increased efficiency of extraterrestrial activities.

Robotic technologies are transforming the approach to spacecraft assembly and maintenance. Their integration into space operations allows for more complex construction, enhances exploration capabilities, and ensures the long-term functionality of equipment in space. Here are some of the most commonly asked questions about the role of robotics in this field.

Robots are crucial in constructing spacecraft by performing tasks that are too dangerous or intricate for humans. For example, on Earth, robotic arms assemble components with precision, while in orbit, they construct large structures and repair satellites, minimizing the risks associated with spacewalks.

Robotics enable the exploration of environments that are inaccessible or hazardous to humans. They advance space exploration by providing capabilities for intricate maneuvering, collecting geological samples, and conducting scientific experiments on distant celestial bodies.

Within extraterrestrial environments, robotic spacecraft serve as scouts, miners, and researchers. They analyze planetary surfaces, search for signs of life, and relay critical data back to Earth. These robotic explorers can endure extreme conditions, from the cold vacuum of space to the searing heat of Venus.

Using robots for maintenance and repair offers significant benefits, such as reducing human exposure to space hazards and extending the lifespan of satellites and space stations. Robotic systems can perform tasks such as refueling satellites, updating systems, and fixing unexpected damages autonomously or with human supervision from Earth or the spacecraft.

Robotic systems enhance the efficiency and safety of space operations by executing tasks with speed and precision. They operate continuously without the need for rest and can be remotely managed, which allows astronauts to focus on research and other critical tasks that require human attention and decision-making.

Robotics play integral roles in the long-term sustainability of space stations by performing regular inspections, repairs, and upgrades. This reduces the need for risky spacewalks and ensures that the space station remains a safe and functional environment for astronauts to live and work in for extended periods.