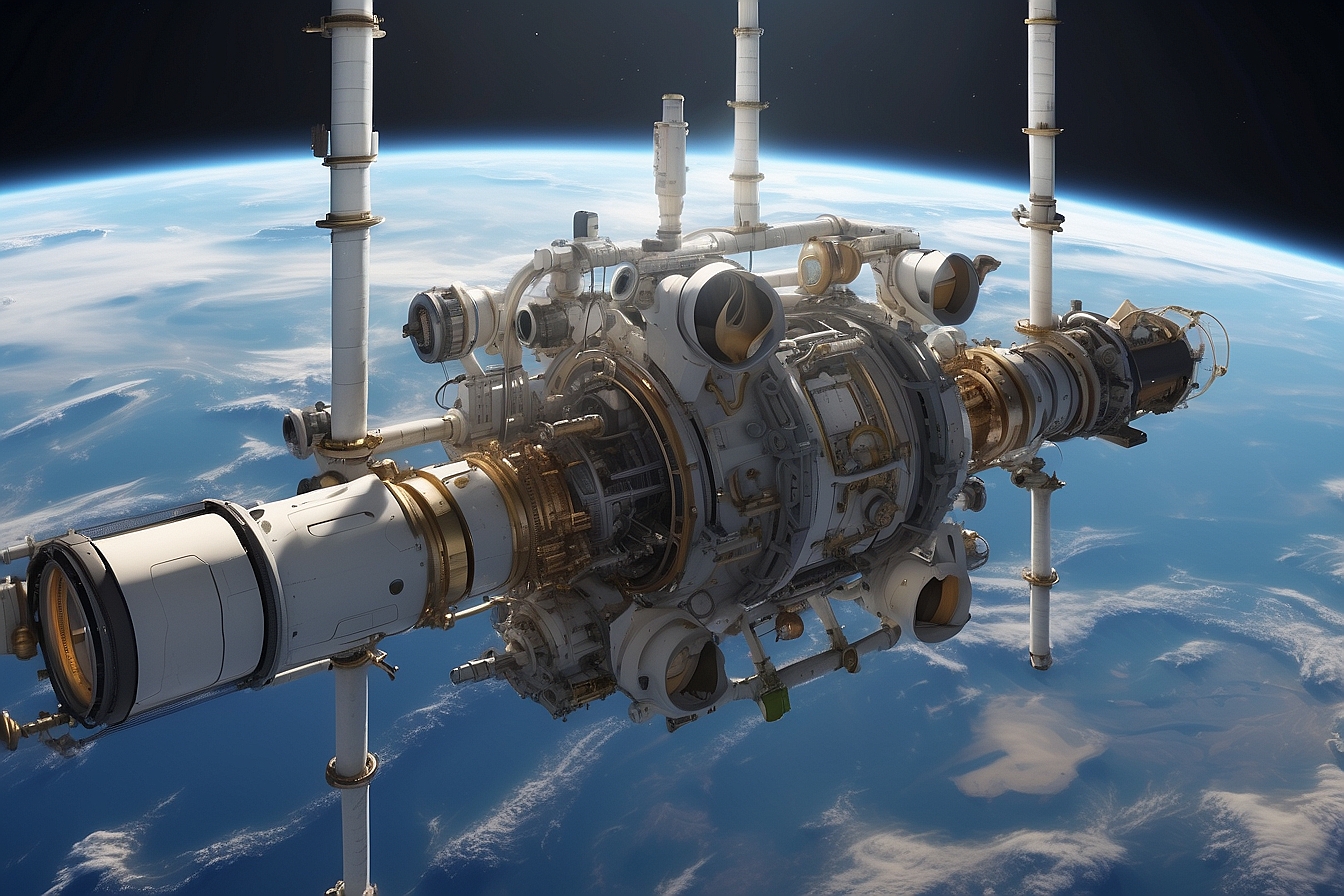

Recycling Life – Living aboard the International Space Station (ISS) presents unique challenges, chief among them being the necessity to recycle life’s most vital resources: water and air. Astronauts in the ISS rely on sophisticated recycling systems to support life in the otherwise uninhabitable vacuum of space. The Environmental Control and Life Support System (ECLSS) on the ISS ensures that the station’s inhabitants have clean air to breathe and water to drink, which are critical for sustaining life during long-duration space missions.

The technology used aboard the ISS represents the pinnacle of human ingenuity, turning waste products back into life-sustaining resources. This includes reclaiming water from the air exhaled by crew members, as well as moisture from sweat, urine, and other waste water. Air revitalization systems also play a crucial role, removing carbon dioxide from the cabin and replenishing oxygen. These systems not only preserve the astronauts’ health but also reduce the need for frequent resupply missions from Earth, which are costly and logistically complex.

The International Space Station (ISS) relies on the Environmental Control and Life Support System (ECLSS) to sustain its crew. This system is responsible for creating a livable environment by managing air and water aboard the station.

ECLSS comprises two key functions, delineated between air revitalization and water recovery.

Air Revitalization:

Water Recovery:

ECLSS represents a feat of engineering, making extended space missions feasible by replicating Earth’s ecosystems. It is an example of regenerative life support systems, which continuously sustain life by recycling resources.

The system is essential for maintaining the well-being of astronauts, reducing the resupply burden from Earth, and is under constant development to support future long-duration missions. The knowledge accumulated from ECLSS contributes significantly to the advancement of life support systems for space exploration.

The International Space Station’s (ISS) Water Recovery System (WRS) is a pinnacle of recycling technology, crucial for long-term human spaceflight. It transforms waste fluids, including urine and humidity from the air, into potable water for drinking and other uses.

The ISS houses an innovative Urine Processor Assembly (UPA) which is central to the system’s capacity to turn urine into water safe for consumption. Initially, urine undergoes a pretreatment to control microbial growth and precipitation of solids. Subsequently, it’s distilled, separating water from waste via the UPA, ensuring astronauts have a continual supply of water for drinking and daily needs.

Sweat and vapor expelled by the crew also become sources for water production. The station’s Temperate and Humidity Control system collects cabin air and funnels the moisture to the Water Recovery System, where it’s reclaimed. This process efficiently recovers water from air humidity, conserving every possible drop in the closed-loop life support system.

Once urine and humidity are processed, the resultant water undergoes further treatment to meet drinking standards. Iodine is added to the reclaimed water as part of the final purification step to ensure potable water is free from any microbial contaminants. The meticulous treatment process underscores the ingenuity behind orbital water recycling, emphasizing the necessity of sustainable practices in space.

The International Space Station (ISS) employs advanced life support systems to maintain a habitable environment for the crew. Air revitalization is vital for the removal of carbon dioxide exhaled by astronauts and the generation of essential oxygen. These tasks are critical for sustaining life aboard the ISS and are accomplished through robust, regenerative systems.

The Carbon Dioxide Removal Assembly (CDRA) uses a series of chemical reactions to scrub carbon dioxide from cabin air. This process safeguards astronauts against the build-up of carbon dioxide, which is a natural byproduct of human respiration. It operates continuously, utilizing materials that absorb carbon dioxide and later release it into space once saturated.

The Sabatier Process plays a key role in the station’s life support system by recycling carbon dioxide into oxygen. This chemical reaction combines carbon dioxide with hydrogen, producing water and methane. The water is then electrolyzed to generate oxygen, ensuring the crew has a steady supply of the air they need to breathe. This method effectively recycles breath, closing the life support loop and reducing the need for oxygen from Earth.

In the drive to extend humanity’s reach into the cosmos, engineers are continuously improving the Environmental Control and Life Support System (ECLSS), a vital component in ensuring astronaut survival during deep space missions. ECLSS advancements play a crucial role in the Artemis program, aiming to return humans to the lunar surface, and in the larger plan for a Mars mission.

Significant ECLSS development focuses on water and air recycling. Recycled water is essential, and NASA has made strides in water recovery, which is crucial for long-duration missions far from Earth. The International Space Station (ISS), in low earth orbit, has been a crucial testbed for these technologies, where systems are engineered to recover close to 98% of water.

| Key Components | Description |

|---|---|

| Oxygen Generation | Conversion of water into breathable oxygen via electrolysis. |

| Waste-water Treatment | Advanced filtration to reclaim potable water from wastewater. |

| CO2 Removal | Technologies to scrub carbon dioxide from the cabin air. |

| Air Revitalization | Systems to maintain air quality and proper mixture of gases. |

Hardware and sensors aboard spacecraft need to be both robust and sensitive to guarantee the continuous, reliable operation of ECLSS. The engineering challenges require innovative solutions by designing efficient and hardy systems capable of maintaining life-supporting environments over vast distances and timeframes.

Space exploration endeavours, such as the journey to Mars, rely on sophisticated ECLSS to utilize resources like water and air almost indefinitely, a concept at the heart of in-space “recycling life.” The lessons learned from these advances not only propel us further into space but also offer sustainable living blueprints for endeavors on the moon, Mars, and beyond.

Maintaining crew health and hygiene in the confines of the International Space Station (ISS) hinges on efficiently managing consumables, particularly water. Astronauts rely on a meticulously designed Water Recovery System (WRS) that transforms wastewater—including urine—into clean water for drinking, food preparation, and hygiene.

Daily Hygiene Operations:

Water Recovery Efficiency:

In the environment of the ISS, a paramount priority is to recycle and purify water to a degree that approaches 98% efficiency. This human life support necessity ensures that the finite resource of water sent from Earth is maximally conserved.

| Consumables Recycled | Description |

|---|---|

| Urine | Filtered and purified for reuse. |

| Sweat and Exhaled Moisture | Captured by dehumidifiers and processed. |

Ensuring the crew can maintain personal hygiene standards is crucial for both their physical well-being and morale. Hygiene routines are adapted for the zero-gravity environment of the ISS. Tools and procedures are in place to make sure that while living in space, astronauts can stay as clean and healthy as they would on Earth. The behind-the-scenes technologies like the WRS represent the silent workhorses that sustain life aboard the ISS.

Bioregenerative Life Support Systems (BLSS) are critical for long-term space habitation, incorporating natural processes to sustain human life. These systems integrate biological components such as plants and microorganisms to regenerate vital resources, aiming to minimize resupply needs and enhance self-sufficiency in controlled environments.

Through the integration of plants into life support systems, NASA and ESA have explored how flora can contribute to vital functions aboard the International Space Station (ISS). Food production within BLSS relies on plants to convert carbon dioxide into oxygen, serving a dual purpose of sustaining crew members with fresh produce while maintaining atmospheric pressure and composition. Essential to this process are nutrients, which must be carefully managed to support plant growth and optimize harvests within the unique conditions of space.

Researchers have found that certain crops such as wheat and lettuce can be particularly effective in space, providing not just sustenance but also psychological benefits to astronauts through the presence of greenery.

Advancements in BLSS also focus on the integration of microbial and microalgae systems. These microorganisms possess the ability to recycle waste products back into usable nutrients and generate oxygen, showcasing a high degree of efficiency in supporting life. Microalgae, for instance, are an area of active research due to their rapid growth rate and high oxygen output. Such systems form a synergy with human inhabitants aboard space habitats, creating a self-perpetuating biosphere that can support life for extended periods.

By harnessing the regenerative capabilities of these organisms, researchers aim to develop robust and reliable BLSS that can support deep-space exploration missions where resupply from Earth is not feasible.

Effective resource management on the International Space Station (ISS) is crucial to maintaining a sustainable environment for astronauts. Key aspects include the storage, recycling, and recovery of vital resources such as food, water, and air.

Water Recovery and Management:

| Water Source | Process Used | Outcome |

|---|---|---|

| Urine | Urea filtering, distillation | Potable Water |

| Sweat | Condensation, purification | Reusable Water |

Air Regeneration:

Food Resupply:

The integration of such systems embodies the efforts to recycle and recover resources in a closed-loop, mimicking Earth’s own cycles. This is instrumental for the ISS, acting as both a dwelling and laboratory for its consumers – the crew. These initiatives also lay the groundwork for future long-duration missions, where sustainable life support will be even more critical.

The development of Environmental Control and Life Support Systems (ECLSS) for the International Space Station (ISS) is a triumph of human ingenuity in the face of extraordinary challenges. Durability is paramount, as systems must operate continuously in the harsh environment of space. Solutions include rigorous testing on Earth and the integration of radiation protection strategies to mitigate the effects of damaging ionizing radiation.

Spares and spare parts management presents another hurdle. With limited payload capacity, frequent resupply from Earth is impractical. To address this, the ISS has embraced 3D printing technology, enabling on-demand manufacturing of certain components.

One persistent challenge lies in the area of water recovery. ECLSS employs intricate processes including nitrification to recycle fluids. The goal is to achieve recirculation rates of over 98%, as suggested by the current status of regenerative ECLSS water recovery systems.

Here is a brief overview of some significant challenges and their ingenious solutions:

| Challenge | Solution |

|---|---|

| System Durability | Advanced materials and shielding |

| Spare Parts Availability | On-station 3D printing |

| Radiation Damage | Enhanced radiation protection |

| Efficient Nitrification | Biological and chemical processes |

| Payload Limitations | Minimizing waste & maximizing reuse |

Maintaining these life-preserving systems in space requires constant innovation and adaptation. This ECLSS development effort not only ensures the well-being of astronauts but also advances our understanding of sustainable living practices for future long-duration missions.

The International Space Station (ISS) is a marvel of modern engineering, particularly when it comes to its life-sustaining systems. Here, we address some of the most common questions regarding how the ISS recycles water and air to support its crew.

On the ISS, water recycling involves collecting moisture from breath and sweat, as well as reclaiming water from urine. The collected water then goes through several filtration and purification stages to remove impurities, making it safe to drink and use again. This recycling process ensures that astronauts have a sustainable and reliable water supply.

Air revitalization on the ISS is critical for removing carbon dioxide and replenishing oxygen. The system absorbs carbon dioxide from the cabin air and processes it through chemical reactions to separate oxygen. In addition, water electrolysis helps generate additional oxygen, ensuring that the astronauts have a breathable atmosphere.

The water recovery system on the ISS employs advanced technologies, including the Urine Processor Assembly and Water Processor Assembly. Together, these systems recover and purify water from urine, sweat, and cabin humidity. A recent milestone showcases their ability to recycle upwards of 98% of wastewater.

The Environmental Control and Life Support System (ECLSS) on the ISS is designed to mimic Earth’s natural systems. It provides and maintains a livable environment by regulating temperature, pressure, and air composition while also managing water and waste. This system is vital for long-term habitability in space.

The ISS water recycling system has achieved impressive efficiency, recycling approximately 98% of all wastewater. This includes moisture from the air and liquid waste. Such efficiency is crucial for reducing the need for water resupply missions from Earth, making long-duration spaceflight feasible.

Wastewater aboard the ISS is treated through a meticulous process that includes filtration, temperature-controlled distillation, and chemical treatment. The goal is to remove contaminants and ensure that the resulting water meets stringent quality standards for consumption and use. This recycled water is vital for ISS crew members, who need to maximize every drop in the closed-loop ecosystem of the space station.