In-space refueling is a pivotal advancement that could redefine the future of space missions, allowing spacecraft to replenish their fuel and extend their operational lifespan beyond initial expectations. This emerging technology represents a game-changer for deep space exploration, providing greater flexibility and efficiency for ongoing and future missions. As the concept gains traction, several innovative companies are spearheading efforts to develop viable in-space refueling systems, eyeing both the strategic and economic potential it holds.

The successful implementation of in-space refueling technology on deep space missions will undoubtedly require a synthesis of robust engineering, substantial investment, and a throng of inter-sector contracts. Recent technological advances are pushing the boundaries of what was once deemed impossible. The continuous evolution of hardware, combined with renewed interest and funding, is propelling the space industry closer to realizing the ambitious goal of fully operational refueling platforms in the cosmos.

The venture towards in-space refueling is paving the way for more sustainable and longer-duration space missions. By mastering the replenishment of spacecraft fuel post-launch, companies are crafting a future where the reach of humanity extends far beyond the moon.

The stewardship of cryogenic fluids like liquid hydrogen, liquid oxygen, and methane is crucial for in-space refueling. These substances, which remain gaseous at standard temperature and pressure, are cooled to extreme temperatures to maintain a liquid state crucial for efficient propulsion. Managing these fluids involves intricate systems to control temperatures and prevent fuel loss, a principle that’s seen significant advancement with innovations in insulation and active refrigeration technology.

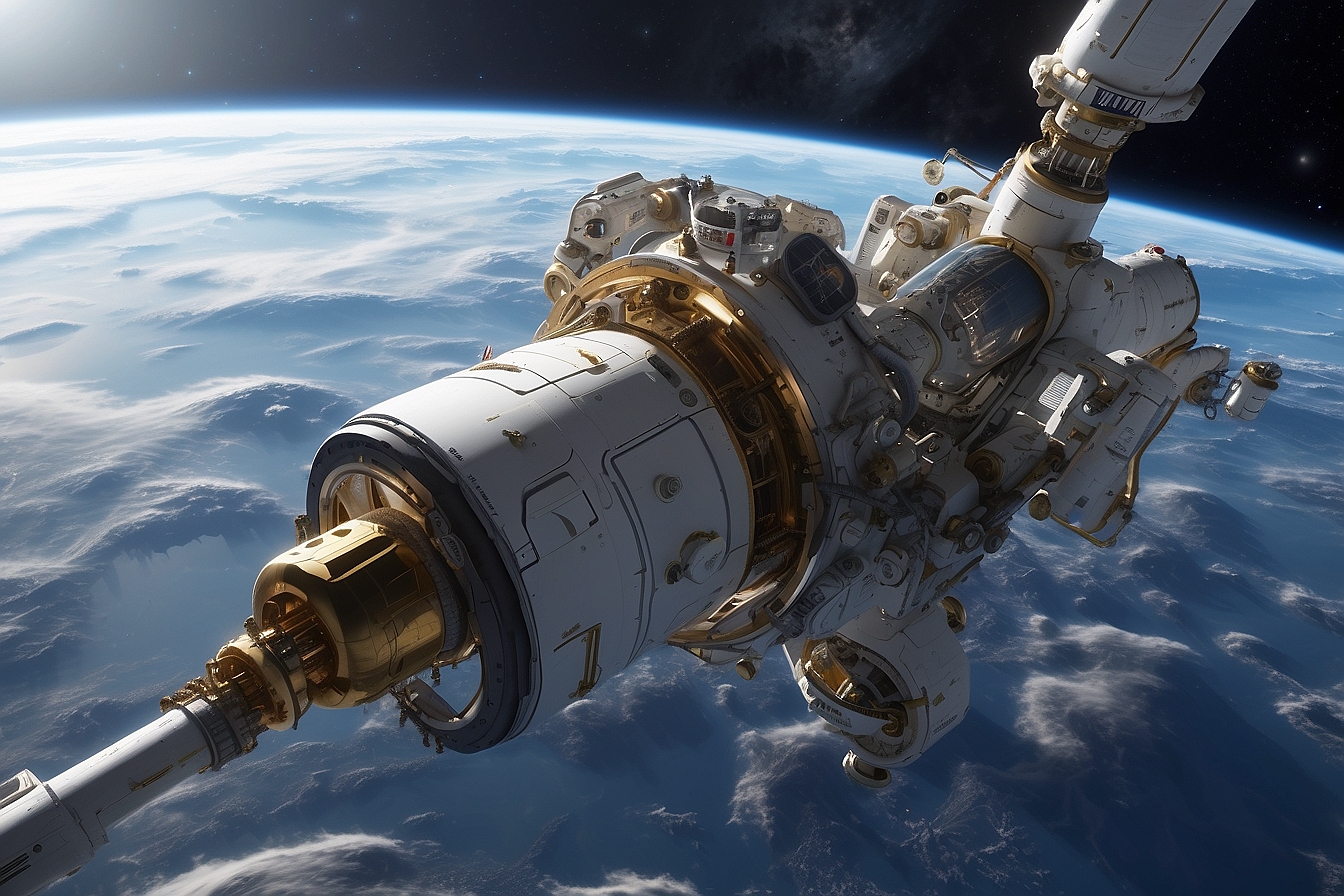

Transferring fuel in space is a delicate operation, with tank-to-tank transfer techniques being developed for this task. These methods must overcome the lack of gravity, ensuring that fuel can be transferred from a storage vessel to a spacecraft’s tank. Techniques such as robotic interfaces and harmonized coupling mechanisms are being pioneered. They are expected to allow precise and controlled fuel transfer, a critical step for reliable in-space refueling.

Efficient fuel storage solutions are critical to the long-term viability of in-space refueling stations. Storing fuel like liquid oxygen and liquid hydrogen in space requires innovative approaches that address the challenges posed by microgravity and the vacuum of space. Advances include multi-layered insulation, sophisticated temperature control, and the development of resilient container materials to minimize boil-off and extend the usable life of stored cryogenic propellants.

This section covers the major organizations shaping the future of in-space refueling, outlining their roles, partnerships, and innovative approaches.

NASA has long been at the forefront of space exploration, and it continues to play a pivotal role in the development of in-space refueling technologies. The agency’s initiatives, such as the ARP (Advanced Refueling Project), involve collaborations with various industry players to extend mission lifetimes and reduce costs. Partnering with companies like SpaceX and Lockheed Martin, NASA is working towards integrating refueling capabilities into future mission designs.

The realm of in-space refueling is witnessing significant contributions from several commercial entities. SpaceX, known for its groundbreaking work in space transport, is actively pursuing refueling technologies for its missions to Mars and beyond. United Launch Alliance (ULA) and Lockheed Martin are also contributing to the advancement of refueling systems with their expertise in aerospace manufacturing and design.

Notably, Northrop Grumman has made strides with its refueling systems, having developed technologies to extend satellite life (satellite-refueling technology). SpaceLogistics, a subsidiary of Northrop Grumman, is another key player offering mission extension services through its spacecraft designed specifically for docking and servicing satellites in orbit.

The innovation is not limited to established giants; newcomers like Rocket Lab Photon are contributing with their versatile space tugs, designed to provide various in-space services, including refueling. Meanwhile, Blue Origin is gearing up to be a significant contender with its vision for space infrastructure and potential refueling stations that could support long-duration missions and deep space exploration.

Recent advancements in in-space refueling technologies are reshaping the potential for long-duration deep space missions. Through the development of sophisticated hardware components, companies are overcoming the challenges posed by the harsh environment of space to create sustainable fueling solutions.

The success of in-space refueling hinges on the integration of advanced robotic arms and docking technologies. These systems enable precise maneuvers and secure connections between spacecraft and fueling stations. Noteworthy in this arena is the Passive Refueling Module (PRM), which is quickly becoming a standard for easy interface and connection. Robotic arms designed for refueling must be both highly dexterous and reliable to manage the intricate process of docking and fuel transfer in the vastness of space.

Sensors and precision landing systems provide the necessary guidance for spacecraft to navigate and dock with fuel depots. Technologies like Lidar and advanced cameras supply real-time data for accurate positioning. Additionally, the Rapidly Attachable Fluid Transfer Interface (RAFTI) developed by companies like Orbit Fab delivers an innovative solution, serving as a universally compatible fueling port that supports in-orbit refueling of a wide array of satellite systems. This interface enhances the agility of satellite operations by streamlining the refueling process.

This section examines specific missions and demonstrations that mark significant advancements in in-space refueling capabilities, crucial for extending space missions and enabling further exploration.

Historic steps toward in-space refueling began with the ISS Mission Extension Vehicle, which successfully docked with the Intelsat satellite to demonstrate mission extension services. Upcoming flight demonstrations are poised to further evolve this technology. For instance, a SpaceX-led initiative aims to conduct in-depth trials on refueling and propellant depots for reusable lunar landers. Envisioned for a 2025 time frame, the U.S. Space Force plans to test satellite refueling in geostationary orbit, ushering in a new era for satellite maintenance and longevity.

Under the leadership of former NASA Administrator Jim Bridenstine, NASA’s ambitious plans include the Artemis program, which seeks to return humans to the Moon. An integral part of Artemis is the Gateway, a lunar orbiting outpost that will serve as a staging point for deep space exploration. One critical aspect of the Gateway is its design to support in-space refueling, which can potentially lengthen its operational life and enhance crewed missions to the Moon. This development paves the way for a sustainable lunar presence and provides insights into logistics for future manned missions to Mars.

The burgeoning field of in-space refueling is revolutionizing how satellites operate, significantly extending mission lifetimes and enhancing orbital maneuverability. Cutting-edge refueling technology is now paving the way for more sustainable and efficient operations in geostary orbit.

The advent of satellite refueling is a game-changer in the space industry, promising the restoration of fuel levels for satellites that were previously deemed non-servicable after their initial fuel depletion. This initiative is led by companies like Lockheed Martin, which is investing in the potential of Gas Stations in Space™ refueling technology. Complicated tasks such as refueling are carried out by intricate robotic systems and tools designed specifically to interact with various interfaces of satellites, each differing in design and function.

Furthermore, satellite servicing goes beyond just refueling; it encompasses maintenance, repairs, and even upgrading systems to enhance performance. Operators perform these tasks remotely, guiding servicing satellites equipped with the required tools and replacement parts. This significantly cuts down on costs and resources since satellites no longer have to be deorbited and replaced as frequently.

Orbital refueling extends mission capacities and enables satellites to maneuver with a freedom that was previously unheard of, leading to advancements in strategic positioning and the potential for avoiding space debris. Specific applications in geostationary orbit—an area far from Earth’s surface where satellites rotate in sync with the planet—stand to benefit immensely. Northrop Grumman, for instance, has made notable progress with its technology, positioning themselves as a leader in the field with their comprehensive refueling architecture solution.

The technology allows for the extension of satellite lifespans, rejuvenating aging assets, and potentially reducing space congestion by minimizing the number of satellites that must be launched. Additionally, with the ability to refuel on orbit, the U.S. Department of Defense and others can adjust their satellite strategies to enhance both the resilience and the capability of their space-based assets.

In-space refueling is a critical technology that has the potential to extend the reach of space missions and ensure continuous military presence in the space domain.

Investing in in-space refueling technologies is essential for supporting sustained exploration missions to the Moon and Mars. For instance, NASA’s Artemis program, aimed at returning humans to the Moon, could benefit greatly from the capability to refuel spacecraft and lunar landers, thus facilitating a continuous human presence and potentially longer missions. Similarly, missions to Mars will require in-space refueling to lower the costs and increase the payload capacities for robotic and crewed missions.

The U.S. Military, particularly through entities like the Space Systems Command and the Defense Innovation Unit, recognizes in-space refueling as a strategic asset. The ability to refuel satellites could ensure that the Pentagon maintains assured access to space in times of conflict, enhancing the resiliency and longevity of critical national security satellites. It also allows for more flexible mission profiles and extends the life of assets already in orbit, which could be a game-changing advantage for the United States.

In-space refueling is positioned to transform the economics of satellites and the sustainability of space exploration. Pioneering companies are working to create a more cost-effective and environmentally friendly future in space.

The ability to refuel satellites in orbit has the potential to greatly extend their operational life, reducing the need for frequent replacements and, therefore, the costs associated with building and launching new satellites. Lockheed Martin’s investment in Orbit Fab’s Gas Stations in Space™ technology plays a crucial role in this advancement, emphasizing both economic value and sustainability. The innovation enhances assured access to space by enabling satellites to maintain their position and functionality for longer periods, thus ensuring a continuous presence and service in space.

Moving towards sustainable practices in space, companies like Astroscale U.S. are not only reducing the costs of in-orbit services through strategic collaborations and advancements but also minimizing environmental impact by mitigating space debris. The Space Force’s contract with the company focuses on developing on-orbit refueling vehicles, supporting both economic and environmental elements of space sustainability. Additionally, SpaceX’s reusability of rocket stages has dramatically decreased launch costs, encouraging a new era where propellant storage and other in-orbit services are more financially viable and environmentally sustainable.

In the push to extend humanity’s reach into the vastness of space, refueling technologies are pivotal. They promise to reshape the landscape of space exploration and human spaceflight.

One significant leap forward is Lockheed Martin’s investment in refueling technology, which targets on-orbit satellite servicing capabilities. This endeavor is set to revolutionize satellite missions by enabling longer lifespans and more versatile maneuverability. The Gas Stations in Space™ refueling technology, for instance, isn’t just a concept—it’s an emerging reality that could redefine operations in Earth’s orbit and beyond.

The implementation of orbital refueling also opens doors to using cryogenic propellants in space, a breakthrough for deep space exploration. Cryogenic fuels, kept at extremely low temperatures, can offer more efficient propulsion compared to traditional chemical rockets. This is particularly crucial for ambitious missions to Mars and other destinations in our solar system.

For space powers across the globe, the ability to refuel spacecraft in orbit is a game-changing asset. The U.S. Space Force, for example, is prioritizing advanced refueling technologies as part of its strategy to ensure greater mobility and flexibility of systems in orbit. The goal is to support a range of operations, from satellite maintenance to potential defense initiatives.

On a grander scale, refueling spacecraft extends the reach of human exploration missions. The prospect of sustainable spaceflight rests on this technology, providing a lifeline for missions that can span years or even decades. It can significantly cut the cost and complexity associated with constructing and launching new space vehicles, thus accelerating the pace of exploration and the quest for scientific knowledge.

The advancements in in-space refueling represent a critical juncture in the expansion of the global space economy, laying the groundwork for deeper space exploration. These efforts, driven by key strategic partnerships between agencies like NASA and leaders in aerospace such as Northrop Grumman, are increasing the longevity and utility of satellites and spacecraft.

Moreover, the future technologies developed for in-space refueling are expected to not only reduce space debris but also enhance the efficiency of ongoing and future deep space missions. By creating the ability to refuel and service satellites on-orbit, the industry is effectively extending mission lifespans and bolstering the infrastructure required for longer voyages, including potential manned missions to Mars and beyond.

The collaboration between government entities and private companies is proving to be a significant driving force within the space sector. Innovations in this field not only have the potential to propel the global space economy to new heights but also inspire the next generation of scientists, engineers, and explorers. Through such collaborative and forward-thinking efforts, humanity’s presence in space will continue to grow, leading to a future where space travel and tourism are accessible realities.

This section is dedicated to addressing common inquiries regarding the burgeoning field of in-space refueling and its pivotal role in shaping the future of deep space missions.

Leading the charge in in-space refueling technologies are companies like Northrop Grumman, which has developed a certified refueling interface system, and Lockheed Martin, with its investment in Orbit Fab’s Gas Stations in Space™ refueling technology.

In-space refueling transforms deep space mission planning by significantly extending the lifespan of satellites and spacecraft. It enables more complex, longer-duration missions by allowing spacecraft to replenish their fuel supplies beyond Earth’s orbit.

Successful in-space refueling requires advanced docking mechanisms, standardized fuel transfer interfaces, and reliable robotic systems capable of operating under the harsh conditions of space. These technologies facilitate secure connection and fuel transfer between servicing and recipient spacecraft.

Space agencies like the United States Space Force are working closely with private companies, selecting partners such as Northrop Grumman to standardize space refueling systems for future logistical networks in orbit.

In-space manufacture and assembly play a substantial role by potentially allowing the construction of refueling stations in orbit, reducing the dependency on Earth-based resources, and streamlining the supply chain for deep space expeditions.

Robotic refueling missions face challenges such as the need for precision automation in an environment with zero gravity and exposure to extreme temperatures. Potential risks include fuel leakage, unintended collisions, and the high cost and complexity of developing autonomous refueling technology.