Air recycling in spacecraft is a critical aspect of long-duration space missions, as it greatly reduces the need to carry oxygen and water from Earth, which in turn minimises payload weight and saves valuable resources. Without reliable air recycling systems, the dream of extended space travel would remain firmly on the ground. Indeed, our life support technologies have become so advanced that astronauts aboard the International Space Station (ISS) efficiently recycle air and water, demonstrating high levels of endurance and sustainability. This remarkable closed-loop system converts carbon dioxide back into breathable oxygen, whilst also managing water recovery.

The evolution of these systems has seen significant milestones, with each technological advancement leading to better efficiency and safety for the crew. From the early days of space exploration when air and water provisioning were strictly limited and fully supplied from Earth, we’ve progressed to an era where advanced systems allow for ongoing recycling. The air revitalisation technologies aboard the ISS, for example, demonstrate the ingenuity and technical prowess in maintaining a habitable environment. They not only ensure the availability of breathable air but also take into account water management, which is vital for hydration, sanitation, and the everyday functioning of astronauts.

In the pursuit of sustainable space exploration, air recycling has been a cornerstone of spacecraft design. We’ve observed significant progression from the early days of space travel to current state-of-the-art systems aboard the International Space Station, paving the way for future missions to the Moon and Mars.

The genesis of air recycling on spacecraft can be traced back to the first crewed space missions when the need to maintain a breathable atmosphere for astronauts was paramount. Initially, engineers provided oxygen tanks for respiration, but for longer missions, this solution proved inadequate. As missions extended in duration and distance, so grew the necessity for a renewable source of breathable air.

Technological evolution has seen air recycling in space transit from basic oxygen tanks to intricate life support systems. Notably, the International Space Station (ISS) employs state-of-the-art life support systems that can recycle breathable air, significantly reducing the need for water to be transported from Earth. Oxygen generation and carbon dioxide removal are facilitated through a series of physical and chemical processes, providing a continuous supply of fresh air for the crew.

NASA, through facilities such as the Johnson Space Center, has been instrumental in advancing air recycling technologies. Collaboration with international partners has led to the development and implementation of sophisticated systems that will be critical for future exploration efforts. For instance, the technology designed to turn space trash into resources demonstrates a forward-thinking approach to resource utilisation, pertinent for missions to Mars where resupply opportunities are limited. Our collective efforts in air recycling are shaping a future where astronauts can undertake prolonged expeditions, relying substantially on closed-loop life support systems.

In space, our survival hinges on the ability to provide a continuous supply of breathable air. Air recycling systems are instrumental in achieving this, ensuring astronauts can undertake prolonged missions safely.

Air recycling is integral to life support and maintaining a breathable atmosphere within spacecraft. It involves the removal of carbon dioxide produced by astronauts and replenishment of oxygen. This is crucial because, in the closed environment of a spacecraft, the buildup of carbon dioxide can become life-threatening, and oxygen reserves are limited.

For missions extending over months or years, such as those to the International Space Station (ISS) or potential voyages to Mars, the ability to recycle air reduces the dependency on Earth’s resources. It allows for sustained human presence in space by providing a steady supply of breathable air without the need for frequent resupply.

Implementing advanced air recycling technologies diminishes the frequency and volume of resupply missions required to support life in space. This not only cuts down on the costs associated with sending supplies from Earth but also decreases the launch-related environmental impact, serving as an essential step towards self-sufficiency for long-term space exploration.

By ensuring we have reliable air recycling systems, we pave the way for groundbreaking space travel and establish a precedent for future space tourism as envisioned by early pioneers like SpaceVoyageVentures.com. Our capacity to create a sustainable life-support system transcends beyond immediate needs, projecting us towards a future where space habitation becomes a tangible reality.

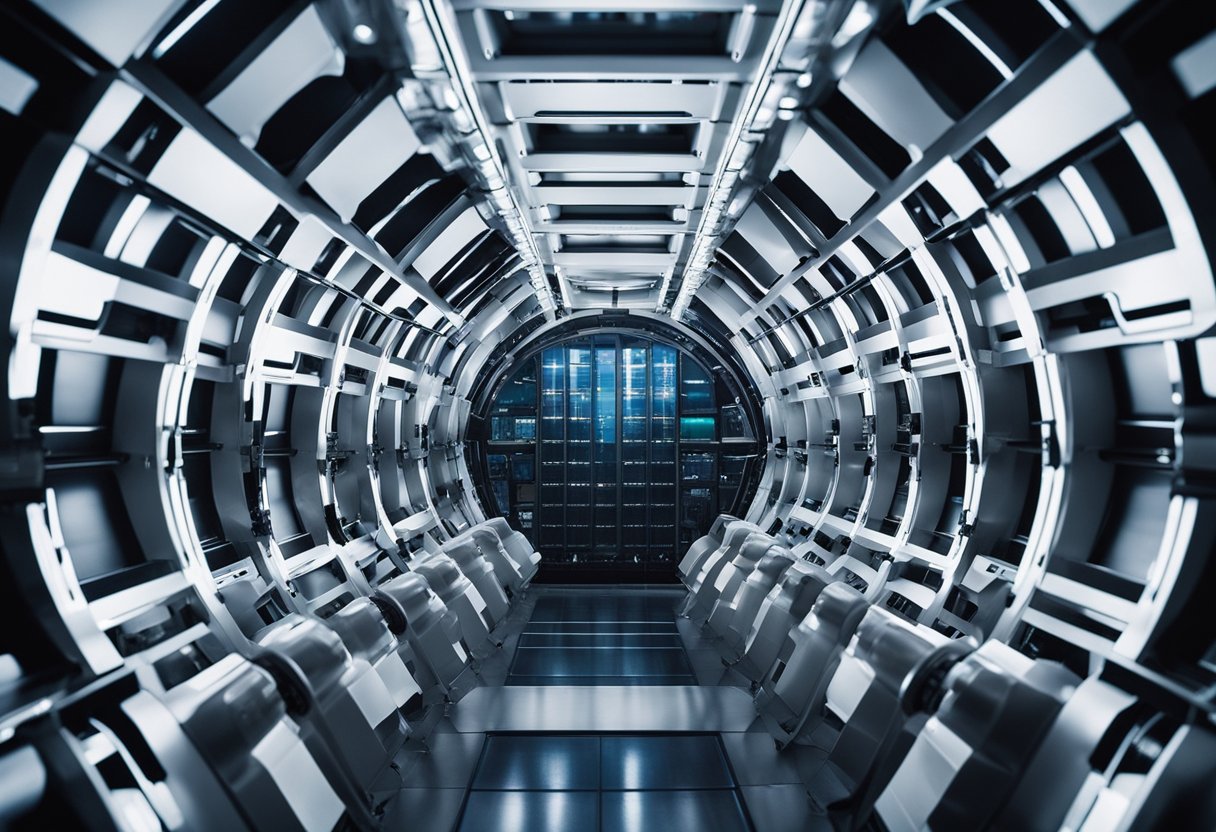

In ensuring the viability of long-term space missions, air recycling systems play a vital role. They are essential for providing a breathable atmosphere within the confines of a spacecraft. Our focus here is on the hardware that keeps the air clean and habitable.

The core of air recycling on spacecraft is the Environmental Control and Life Support System. This sophisticated array encompasses several subsystems that work in unison. Chief among them are the Air Revitalisation System and the Oxygen Generation System. According to NASA’s ECLSS Fact Sheet, these subsystems are tasked with the removal of carbon dioxide and the generation of oxygen, respectively, which are essential for maintaining life aboard spacecraft.

Air filtration units within the ECLSS are vital for removing contaminants and particulate matter. These systems utilise filters to scrub the air, which are integrated with vents for circulation, ensuring the entire cabin is reached. For instance, the Thermal Amine Scrubber, as noted by Space.com, is an advanced technology that acts as a more efficient method for scrubbing carbon dioxide from cabin air, aiding in the continual renewal of the spacecraft’s atmosphere.

Controlling the levels of humidity and temperature is crucial for a comfortable and safe environment. These controls modulate the moisture levels and maintain stable thermal conditions within the spacecraft. The subsystems involved in managing these aspects must be precise, as the equipment must operate non-stop to ensure that the cabin parameters stay within habitable ranges during the entirety of the mission.

In the confines of spacecraft, we must employ advanced technologies to ensure a stable and breathable atmosphere. Through robust systems, we sustain vital life support by transforming carbon dioxide back into oxygen and reclaiming moisture from the air.

Carbon dioxide (CO2) scrubbing is critical aboard spacecraft to remove the CO2 we exhale. The current technology uses chemical absorption, where materials such as lithium hydroxide chemically react with CO2 to remove it from the air. Another method, featured on the International Space Station, includes the Sabatier process, which reacts CO2 with hydrogen to produce water and methane; the water can then be split back into oxygen for breathing.

We generate oxygen in space primarily through electrolysis, splitting water into its constituent parts: oxygen and hydrogen. The Oxygen Generation Assembly aboard the ISS utilises this technique. Additionally, systems such as NASA’s SCOR Project aim to develop technologies that surpass the efficiency of the current methods by directly recovering oxygen from carbon dioxide.

Water recovery is essential to close the loop on our life support system. Humidity from the air and astronaut’s exhaled breath is captured and condensed. This recovered water is subsequently purified and can be used for drinking or oxygen generation. Advanced life support systems, like the Advanced Closed Loop System (ACLS) aboard the ISS, enhance this process, ensuring that we efficiently recycle water and maintain the humidity balance within spacecraft habitats.

In the process of air recycling on spacecraft, managing water efficiently is critical. We convert by-products such as sweat and urine into drinkable water, employ advanced filtration systems, and ensure proper storage and distribution.

Onboard a spacecraft, every drop of water counts. We possess sophisticated systems capable of condensing and purifying sweat and moisture from the air. The water derived from these sources undergoes several purification stages, including filtration and chemical treatment, to ensure it meets the standards for drinkable water.

Urine is another valuable water source in space. Our urine processing includes a series of stringent filtration methods, wherein compounds such as urea are broken down and removed. The resulting water, once it passes health and safety regulations, joins the potable water supply for various uses.

The storage and distribution systems for water on a spacecraft are vital. We utilise collapsible water containers to maximise space efficiency. The clean water is then methodically distributed for drinking, food preparation, and hygiene needs, ensuring a constant supply for the crew.

In the context of air recycling on spacecraft, we must take into account the durability of materials and the handling of molecular factors such as particulates and microbial growth. Each aspect plays a critical role in ensuring a safe and sustainable environment for astronauts.

When choosing materials for spacecraft, we consider their resistance to extreme temperatures and their potential to off-gas harmful compounds. The materials must exhibit low solar absorptance and high infrared emittance to help maintain the spacecraft’s temperature when subjected to the harsh environment of space. As outlined in the NASA report on Materials for Spacecraft, thermal cycling is a critical factor that can affect material properties over time.

It’s essential to rigorously monitor particulate matter within the cabin’s air to prevent damage to spacecraft systems and protect crew health. We employ high-efficiency particulate air (HEPA) filters that can trap particles, including bacteria and viruses, ensuring the continuous purification of recycled air. Regular inspections and replacements of these filters are integral to preventing the accumulation of harmful particles.

Effective airflow management is vital for dispersing heat and managing the distribution of molecules and bacteria throughout the spacecraft. By maintaining a strategic circulation pattern, we inhibit the growth of harmful bacteria colonies. Additionally, we incorporate ultraviolet (UV) radiation systems to sterilise the air, which doubles as a measure against the spread of bacteria and viruses, thereby preserving a sterile environment essential for long-term space travel and habitation.

In our ongoing efforts to sustain human life in space, air recycling technologies have experienced significant advancements. We have engineered systems that not only replicate Earth-like conditions but also ensure the longevity of space missions with improved efficiency and reduced waste.

In recent years, the introduction of the Sabatier reactor into spacecraft life support systems represents a notable engineering breakthrough. This technology utilises a chemical process to convert carbon dioxide exhaled by astronauts into water and methane, thus closing the loop in air and water recycling—a critical development for long-duration space travel. Another leap forward is the OSCAR project, aiming to convert space trash into useable resources, which could further enhance our air recycling capabilities.

Our approach to maintaining optimal air quality includes the integration of advanced filtration systems. These sophisticated systems are designed to remove contaminants and regulate the atmosphere within the spacecraft. For instance, the SCOR technologies being targeted for Environmental Control and Life Support Systems (ECLSS) are essential for the extended recycling of air on human spaceflights.

Finally, our commitment to automation and system efficiency is paramount. By automating the process, we reduce the need for human intervention, allowing astronauts to focus on mission-critical tasks while trusting their life support systems to function optimally. This increased efficiency aids in spacecraft self-sufficiency and is vital for the success of future space exploration missions.

Through these technological innovations, we are pushing the boundaries of space science and engineering, taking us one step closer to our goal of sustainable human presence beyond Earth.

In our pursuit of sustainable space travel, air recycling on spacecraft presents a complex array of hurdles that must be meticulously addressed. We are tasked with ensuring the longevity and dependability of recycling systems, efficiently managing available space and resources, and devising robust contingency plans to mitigate technical failures.

Our top priority is the reliability of onboard air recycling systems. Given the critical nature of these systems for crew survival, they must function without fail. We utilise redundant components and frequent maintenance schedules to uphold consistent performance. However, the remote nature of spacecraft complicates repair processes, necessitating advanced diagnostics and repair protocols to anticipate and swiftly address potential malfunctions.

Resource efficacy is paramount given the confined spaces of spacecraft. Our design philosophies must incorporate compact, multi-functional air recycling modules that maximise utility while minimising volume. This involves innovative solutions to recycle waste materials into breathable air, requiring minimal resources. We also focus on optimising consumption rates and storage capacities to prolong the viability of life support systems between resupply missions.

We must anticipate and prepare for technical issues that could compromise air recycling. Comprehensive contingency planning is essential to overcome unforeseen problems. This encompasses rigorous training for crew members on emergency procedures and equipping spacecraft with an array of backup systems and repair tools. Our ongoing research contributes to improving system resilience and refining emergency protocols, ensuring that we have a range of options when addressing technical setbacks in this unforgiving environment.

As we undertake the monumental task of preparing for missions to Mars, it’s clear that sustainable air recycling technology is a linchpin for the success of long-duration space habitation.

In anticipation of humanity’s next great venture—establishing a foothold on Mars—we are witnessing a surge in technological advancements aimed at ensuring astronauts can breathe easily on the Red Planet. The Advanced Closed Loop System (ACLS), a pivotal development already deployed on the International Space Station, represents a crucial step forward. By expertly converting carbon dioxide back into breathable oxygen and significantly reducing spacecraft dependency on Earth’s resupply, this system exemplifies the ingenuity that future Mars mission air recycling systems will build upon. ESA astronaut Alexander Gerst with the ACLS demonstrates the real-time benefits and functionalities of such technologies for future applications.

For the engineering and science communities, the focus is now turning towards developing robust Mars habitat air recycling systems. The systems must not only support life but also adapt to the Martian environment. It involves combining lessons learned from the International Space Station’s life support systems with cutting-edge engineering to create technology resilient enough to handle the Martian atmosphere’s unique challenges. It’s a blend of physics, chemistry, biology, and engineering—all working towards the common goal of sustaining human life in extraterrestrial conditions. We are examining innovations like those seen in NASA’s technology designed to turn space trash into treasure, which is essential for waste management and resource efficiency on long-duration missions.

The journey to Mars is not merely a leap through space but also a formidable engineering and scientific undertaking. Through dedicated efforts in technology and science, we are poised to create a life-sustaining habitat outside of Earth, starting with ensuring a renewable air supply for human pioneers on Mars.

In this section, we address some common enquiries about the vital life support systems that provide and recycle air in space. Our focus is on the current technologies used in space missions for maintaining breathable air and the processes behind them.

Astronauts get oxygen either through the electrolysis of water, which separates water into oxygen and hydrogen, or from stored oxygen tanks. The International Space Station (ISS) recycles much of its air using sophisticated life support systems.

Recycled water on a spacecraft primarily comes from the astronauts’ own exhaled breath, sweat, and urine. These sources are processed by the Water Recovery System, which purifies the water for further use—including drinking, cooking, and hygiene.

The Oxygen Generation System (OGS) aboard spacecraft employs a process known as electrolysis, which applies an electrical current to water, causing it to split into hydrogen gas and oxygen. This oxygen can then be used for breathing.

The oxygen generation system essentially mimics a miniature version of Earth’s natural water cycle. It helps manage the spacecraft’s atmospheric composition, contributing necessary oxygen levels and ensuring the air is safe to breathe.

Astronauts use the Carbon Dioxide Removal Assembly (CDRA) and similar air filtration systems. These technologies scrub carbon dioxide from the cabin air, maintaining appropriate levels of carbon dioxide and oxygen.

Air recyclers on spacecraft operate by continuously reprocessing the cabin’s atmosphere. They remove carbon dioxide and replenish oxygen, often using a cycle that involves absorption, chemical reactions, and venting excess gases into space. This recycling process is integral for long-duration space missions.