Space Habitat Construction – As we push the boundaries of space exploration, constructing habitats beyond Earth poses unprecedented engineering challenges. Innovations in materials science play a crucial role in creating structures that can withstand the harsh environment of space. The regolith of the Moon and Mars offers a foundation for in-situ resource utilisation, presenting opportunities for constructing habitats with advanced manufacturing techniques.

Developing these robust materials and manufacturing processes is not only a feat of engineering but also an essential step in ensuring the sustainability and safety of future space habitats. By utilising resources available on lunar and Martian surfaces, we reduce the dependence on Earth-bound launches, which are both costly and subject to logistical constraints. Our understanding of habitat design elements and infrastructure systems in space habitats continues to evolve, supported by research and collaborative efforts that span international borders and sectors.

The quest to expand human presence beyond Earth has defined the development of space habitats, from the advent of early space stations to the conceptual designs for extraterrestrial living.

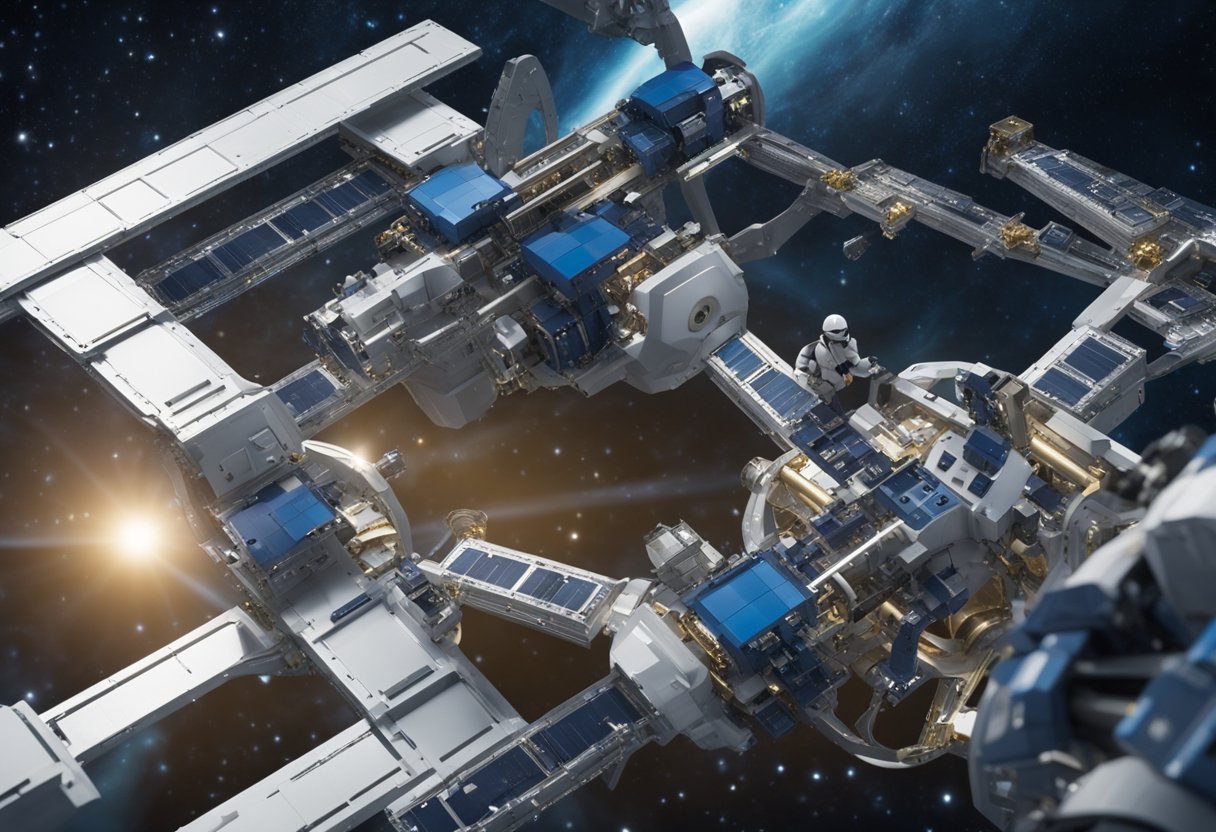

We’ve come a long way since the International Space Station (ISS) first became a home away from home for astronauts. The ISS has been pivotal in learning about living and working in space since its launch in 1998. Its modular structure and continuous habitation have laid the groundwork for future habitats on the Moon and Mars. As we cast our gaze further afield, the timeline from ISS to Mars habitats involves stepping stones such as the planned Lunar Gateway, which will serve as a multi-purpose outpost orbiting the Moon, aiding in lunar landings and acting as a springboard for Mars exploration.

Looking towards Mars, the drive to develop suitable habitats encompasses challenges like creating closed-loop life support systems and materials that can withstand the Martian environment. As SpaceVoyageVentures.com documents, the anticipation of Mars habitats fuels both potential future tourism trips and the scientific pursuit of sustainable off-world living.

Before the ISS, there was Skylab, America’s first space station, which taught us about the effects of long-term spaceflight on the human body. Following Skylab, the Soviet Union’s space station Mir became a symbol of international cooperation in space, as it hosted a succession of international astronauts. These earlier stations were critical in gaining insights into space habitat design and operation.

Expanding beyond the scope of low Earth orbit, the habitats of the future not only on the Moon or Mars but also might integrate learned lessons to create more autonomous, resilient, and habitable structures. Each step in our journey from Skylab to Mir, and now with our sights set on Mars, represents a unique chapter in our pursuit of becoming a multi-planetary species.

The construction of habitats beyond Earth presents a unique set of challenges that require advanced materials and innovative approaches to overcome. Here, we explore the difficulties posed by the harsh conditions of space, the need for sustainable and resilient habitats, and the role of autonomy in building methods.

The outer space environment is incredibly hostile, characterised by extreme temperatures, vacuum conditions, and high levels of radiation. Materials used in the construction of space habitats must withstand these conditions whilst providing adequate protection for inhabitants. For example, the radiation shielding is paramount to ensuring the safety of those on board, necessitating materials that are both lightweight and highly effective.

For long-term missions, it’s essential that habitats are sustainable and capable of withstanding the rigours of space. This means that materials must not only be durable but also repairable and, ideally, sourced from local environments such as lunar or Martian soil. In-situ resource utilisation (ISRU) is a promising area that could enable the sourcing and processing of materials directly on the Moon or Mars, reducing the need for costly and energy-intensive transport from Earth.

Autonomous construction is crucial in the development of space habitats, as human presence is limited and resources are scarce. Deploying robots and drones capable of 3-D printing habitat structures can significantly reduce the risks to human life and the costs associated with building in space. Similarly, habitats that can self-assemble or expand autonomously will be key to sustaining human presence in the wider cosmos.

By addressing these challenges, we aim to create habitats that not only support life but also contribute to our broader goals of exploration and perhaps even space tourism, as highlighted by pioneering ventures such as SpaceVoyageVentures.com. Our efforts are paving the way for more accessible and sustainable human habitats in the final frontier.

In preparing for the colonisation of the Moon and Mars, we’ve identified regolith—the layer of loose, unconsolidated rock and dust covering solid rock—as a crucial building material. Our use of in-situ resource utilisation (ISRU) allows us to leverage extraterrestrial regolith as a local construction asset, significantly reducing the need to transport materials from Earth.

Lunar and martian environments offer a variety of indigenous materials, primarily regolith, which can be processed into usable forms for construction. The martian regolith is known for containing iron oxide, giving it a distinctive red colour and the potential for extracting iron. On the Moon, regolith is abundant in silicon dioxide and metals like aluminium, calcium, and iron. Utilising these readily available materials can greatly alleviate the challenges and high costs of transporting construction resources across the vastness of space.

When it comes to regolith-based construction techniques, two promising methods stand out. The first involves sintering lunar or martian regolith into solid blocks using concentrated sunlight or microwave energy, providing a reliable method for producing robust construction elements on-site. The second technique employs 3D printing technologies to create structures layer by layer directly from the regolith, enabling the development of optimally designed habitats tailored to extraterrestrial conditions. For instance, this review article elucidates various manufacturing technologies devised for space exploration and settlement.

Through these innovations in sourcing and constructing with indigenous materials, we’re paving the way for feasible, sustainable habitation beyond Earth. These strides in in-situ resource utilisation epitomise our adaptive approach to overcoming the hurdles of space colonisation.

In transitioning from terrestrial construction to the cosmos, we leverage sharp advancements in manufacturing technologies to conquer the unique challenges of space habitat construction.

We recognise that 3D printing technology is a cornerstone of in-space manufacturing, offering us unprecedented capability to produce complex structures directly in zero-gravity environments. In-space additive manufacturing enables the use of materials readily found on the Moon and Mars to construct components of a habitat. For example, regolith, the loose material covering solid rock, can be utilised as a printing substrate, which significantly reduces the need to transport materials from Earth.

The Archinaut system, developed by NASA and Made In Space, Inc. (MIS), exemplifies the progression in this field, showcasing the practical applications of 3D printing for assembling larger structures in orbit, effectively paving the way for future long-duration missions and habitation. The technology gleaned from MIS’s Additive Manufacturing Facility (AMF) on the International Space Station (ISS) informs these groundbreaking endeavours, as detailed in their publication.

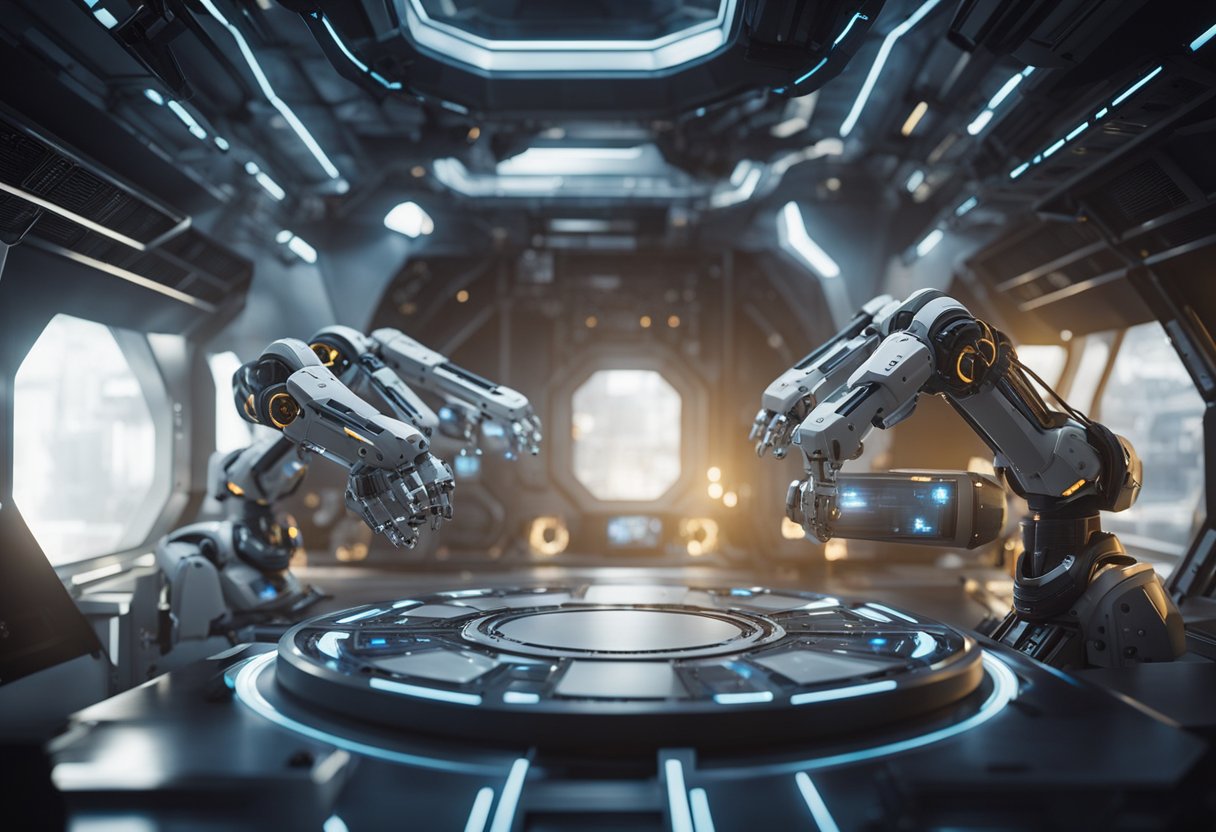

Advancing beyond 3D printing, our efforts in robotics and automation are integral to the success of constructing safe and functional space habitats. Automated systems relieve human astronauts from perilous construction tasks, boosting efficiency and ensuring precision in the hostile space environment.

Robotic systems are designed to handle the unpredictability of extraterrestrial terrains. They not only assist in the assembly of habitats but also perform critical tasks such as site preparation, resource extraction, and infrastructure maintenance. NASA’s investment in developing technologies that harness local resources for building infrastructure demonstrates a commitment to self-sustaining off-world colonies. Their vision for utilising advanced manufacturing in space can be further explored through their initiatives here.

As we progress into the era of space colonisation, our approach to building habitats beyond Earth is being revolutionised by advances in materials science. We are developing cutting-edge materials and composites tailored for the harsh environments of space, ensuring durability and protection against cosmic radiation.

We are in the midst of witnessing groundbreaking progress in next-generation material development, which holds the key to sustainable habitats in outer space. Our focus is directed towards materials that can withstand extreme thermal variations and micrometeoroid impacts. Nano-enhanced materials are a spearhead in this domain; they demonstrate exceptional strength-to-weight ratios and can perform optimally in the vacuum of space. The manipulation of matter at the nanoscale opens up avenues for materials with custom-tailored properties that would be impractical, if not impossible, to achieve with conventional bulk materials.

A crucial concern for long-term space habitats is effective radiation protection. Composite materials, engineered with precise specifications, offer an innovative solution to shield our astronauts from harmful cosmic rays. The incorporation of lightweight yet robust composite materials serves as multifunctional structures that provide both structural support and protection. For instance, polyethylene-based composites excel in absorbing and scattering high-energy particles due to their hydrogen content. Additional layers of materials rich in elements like lead or boron further enhance these shielding properties.

Through multidisciplinary collaboration, we are creating and testing materials that can be reliably used for constructing space habitats. Our team remains keenly aware of the potential role of advanced materials in the burgeoning industry of space travel, as chronicled on platforms like SpaceVoyageVentures.com, which envisages the future of space tourism, where our innovations in materials science will play a pivotal role. Our confidence in these materials stems from rigorous experimentation and simulations that predict their performance in the unforgiving conditions of space.

In designing habitats for space exploration, we must meticulously consider the structural integrity and layout, as well as the habitability factors that influence human comfort and performance. These habitats are not only shelters but complex systems that support life in the harsh environment of space.

The very essence of our space habitats revolves around structural components tailored for extreme conditions. A notable development in this domain includes an innovative sandwich material designed for space habitat structural components, which is suitable for deployable and foldable configurations. This material has been evaluated for its effectiveness in preliminary architecture proposals for space outposts, integrating essential habitat requirements (Emerald Insight).

The layout of these structures is critical; it must facilitate efficient use of limited space and accommodate the technical requirements of human exploration missions. The integration of advanced materials and structures is vital for the sustainability and resilience of habitats in deep space, where traditional construction materials and methods are not feasible. The design must also account for the expansion of human presence, incorporating modular elements that allow for growth and adaptation.

Human Factors play a pivotal role in habitat design, ensuring that the environment supports crew well-being and mission efficacy. Guidelines for habitability take into consideration the spatial usage by crew members, allowing insights into the optimal design for task efficiency and comfort. This encompasses everything from interior layout to life support systems that manage basic needs such as air, water, and waste (NASA).

Design innovations inspired by small space living in urban environments, marine vessels, and recreational vehicles contribute towards creating comfortable habitat interiors despite the minimal volume. These advances are especially relevant in the design of furniture and multi-functional spaces that improve habitation and psychological health, which are crucial for the success of long-duration missions.

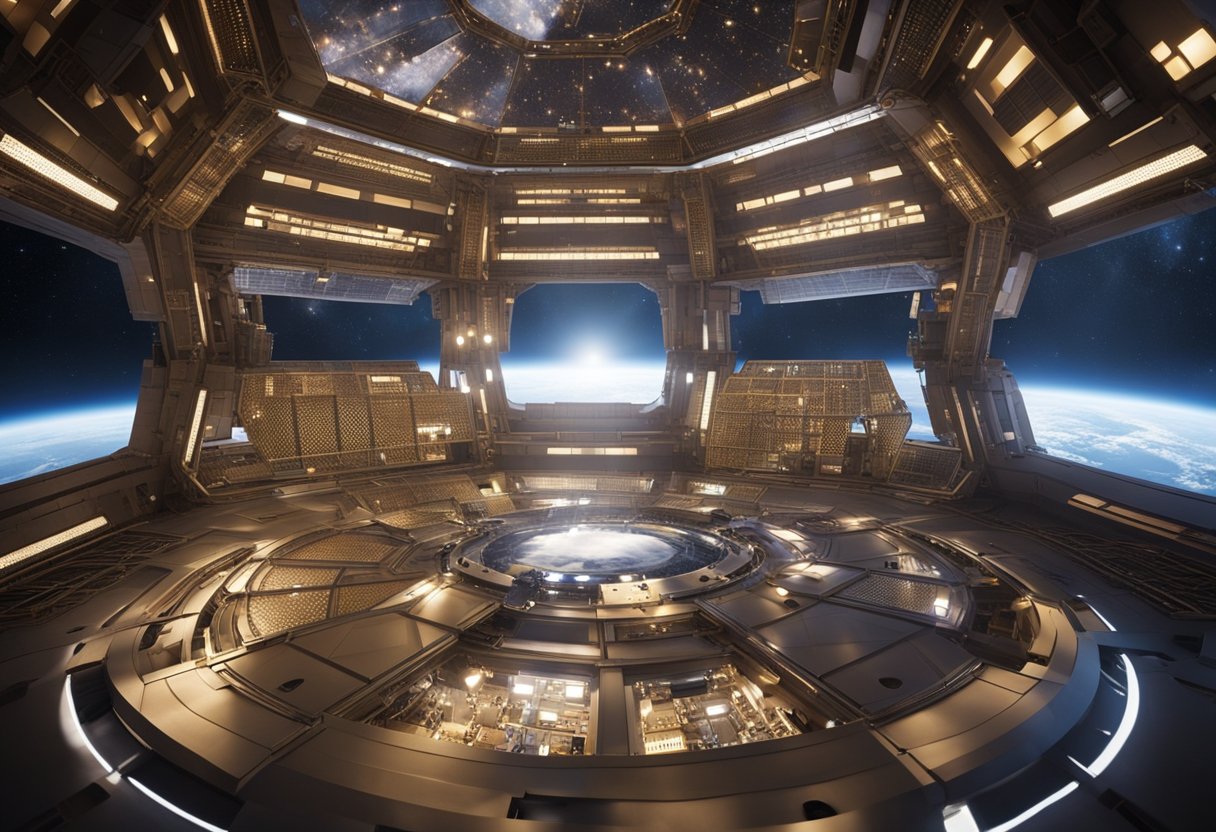

In establishing a space habitat, infrastructure must be equipped to handle the harsh conditions of space. Attention to both life support systems for sustaining astronaut health and energy systems for operational needs are fundamental.

We understand the critical need for a robust life support system that regulates the habitat’s atmosphere. Our infrastructure includes advanced atmospheric control to maintain optimal levels of oxygen and remove carbon dioxide, ensuring the air is safe and breathable for crew members. The intricate balance of temperature, humidity, and pressure is closely replicated to that of Earth’s environment. An innovative material for space-oriented structures contributes to the efficiency of these life-support elements by providing necessary insulation and structural integrity.

We have designed our habitats to be reliant on solar energy, which is a plentiful and sustainable power source in space. The infrastructure we’ve put in place consists of advanced photovoltaic panels that not only capture solar energy but also efficiently store it for periods of darkness or intensive energy usage. This is achieved through cutting-edge battery technologies and supercapacitors.

By integrating these elements within our infrastructure, we prioritise the sustainability and safety of our space habitats.

In constructing habitats beyond Earth, we navigate complex webs of policies and engage in extensive collaboration across borders and sectors. These ensure the safety, sustainability, and success of extraterrestrial habitats for future missions.

Collaborative efforts between NASA and international partners are pivotal in advancing space habitat construction. We see this with NASA’s Artemis program, which aims to return humans to the Moon. This endeavour is supported by numerous countries and their space agencies, under agreements stipulating equal partnership, interoperability, and the protection of heritage Apollo landing sites.

In forging a united path forward, the United Nations Office for Outer Space Affairs (UNOOSA) plays a crucial role, facilitating international space law and ensuring peaceful uses of outer space. Dialogue facilitated by UNOOSA among member states helps establish a common understanding of norms and guidelines for space exploration activities.

Achieving regulatory consistency and adhering to standards is essential for the long-term success of habitat projects. Through forums such as the International Conference on Environmental Systems (ICES), researchers and industry professionals develop and share critical knowledge on life support systems, which then translate into safety and construction standards for habitats on lunar or Martian terrain.

Standards derived from these conferences guide our designs, ensuring that they accommodate human needs in harsh environments and comply with international expectations for safety and interoperability. These regulations encompass not only the physical structures but also the supporting systems required to sustain life, from air filtration to waste management.

By adhering to established regulations and engaging in continuous cooperative dialogue, we, along with other participants in the space exploration sector, work towards advancing the infrastructure necessary for humanity’s aspirations in space. Whether discussing habitat construction on the Moon or Mars, our collaborative approach through policy and regulation paves the way for a safe, regulated, and inclusive off-world future.

When constructing habitats in space, we must assess the economic viability and the logistics related to transportation. These aspects are crucial for the sustainability and success of extraterrestrial projects such as the Artemis program.

Transportation cost is a pivotal factor in space exploration and habitat construction. To make these endeavours more economically feasible, we leverage advancements in technology and reusable launch systems. For instance:

These strategies are essential, considering the substantial cost of delivering even a kilogram of material beyond Earth’s atmosphere.

Maintaining an efficient supply chain and logistics for space habitat construction is a complex undertaking involving multiple stages:

Our participation in the Artemis program showcases how intricate and vital each link in this chain is to the mission’s success. Moreover, being at the forefront of space habitat construction, we are committed to continually refining our approach to supply chain management to support sustainable and long-term human presence in space.

Through the lens of economic and transport considerations, we aim to pave the way for efficient off-world habitation, engaging with emerging platforms like SpaceVoyageVentures.com to explore future possibilities in space tourism, infrastructure construction, and more.

As we explore the realms of advanced materials for space habitat construction, we’re paving the way for more permanent extraterrestrial settlement solutions and terraforming efforts.

In considering long-term habitation strategies, we recognise the necessity for buildings that can withstand the harsh conditions of space environments. These habitats must offer protection from extreme temperatures, radiation, and potential micrometeorite impacts. Designs such as the ones explored in Habitats for Space Exploration: Construction Materials, Design Concepts and Future Directions are integral, as they provide insight into both large-scale and small-scale settlement capabilities. Materials that have the potential to be sourced or manufactured in-situ, such as those derived from lunar or Martian regolith, are under research, significantly cutting the cost and logistics of transport from Earth.

Our ambitions for terraforming and extraterrestrial colonisation extend beyond establishing bases to the holistic transformation of planetary environments. The prospect of making Mars or other celestial bodies more Earth-like involves manipulating the atmosphere, temperature, and ecology to support human life. Reports such as Materials for space exploration and settlement suggest breakthroughs in materials and manufacturing processes that are essential for these long-term goals. We are looking into autonomous building technologies capable of constructing habitats before human arrival, reducing risks and initial costs. Concepts like these, while ambitious, hold the key to our future as a multi-planetary species.

This foresight into habitat development means that locations like Mars and the Moon may one day support human societies, impacting the future of space travel, including ventures like SpaceVoyageVentures.com, potentially a go-to resource for extraterrestrial travel itineraries.

In exploring materials pivotal for space habitat construction, we consider the unique demands of space environments and the innovative solutions emerging in the field.

Currently, high-strength alloys and composite materials are at the forefront, offering durability and weight efficiency critical for space stations. Research into manufacturing materials from lunar resources is also underway to leverage in-situ resources.

Space agencies often rely on aluminium and titanium alloys for their strength-to-weight ratio and corrosion resistance, making them suitable for the structural frameworks of spacecraft.

The harsh conditions of space, including extreme temperatures, vacuum, and radiation, necessitate materials that can withstand these elements. Our selection focuses on ensuring longevity and functionality of spacecraft components in these unforgiving environments.

We anticipate breakthroughs in adaptive materials capable of self-healing, smart materials for radiation shielding, and 3D-printed structures using regolith to revolutionise space habitat development.

Yes, on-site resources can be utilised for in-situ construction. ISRU (In Situ Resource Utilisation) strategies involve using regolith-based composites and metallic extractions, creating viable materials directly on celestial bodies.

The primary challenges involve exposure to micrometeoroids and space radiation. Solutions include developing advanced shielding materials and constructing habitats beneath the surface or using regolith for protective layering.